Numerical study on hydraulic failure characteristics of deep-buried solution-fissured limestone as an inrush prevention layer

-

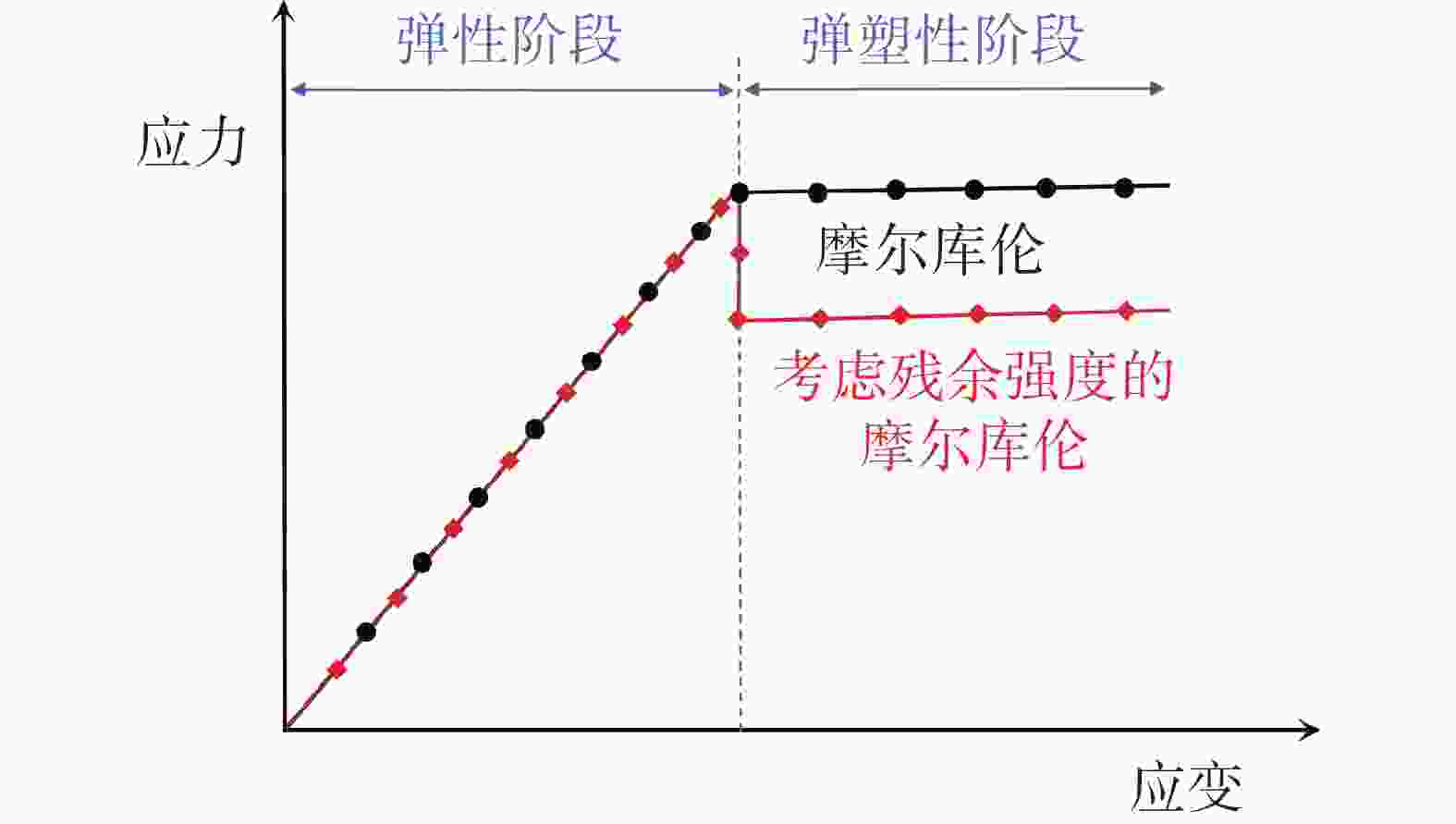

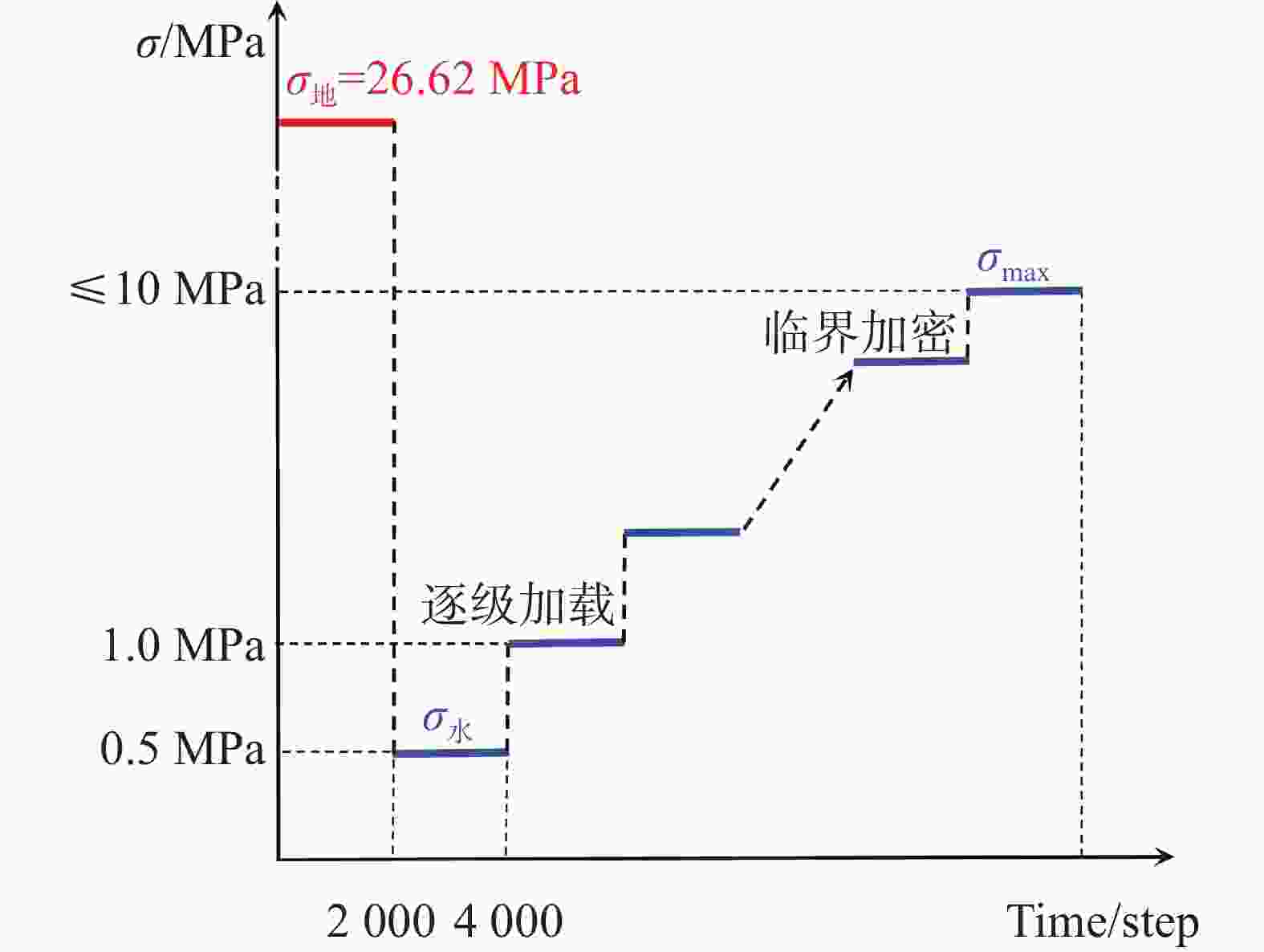

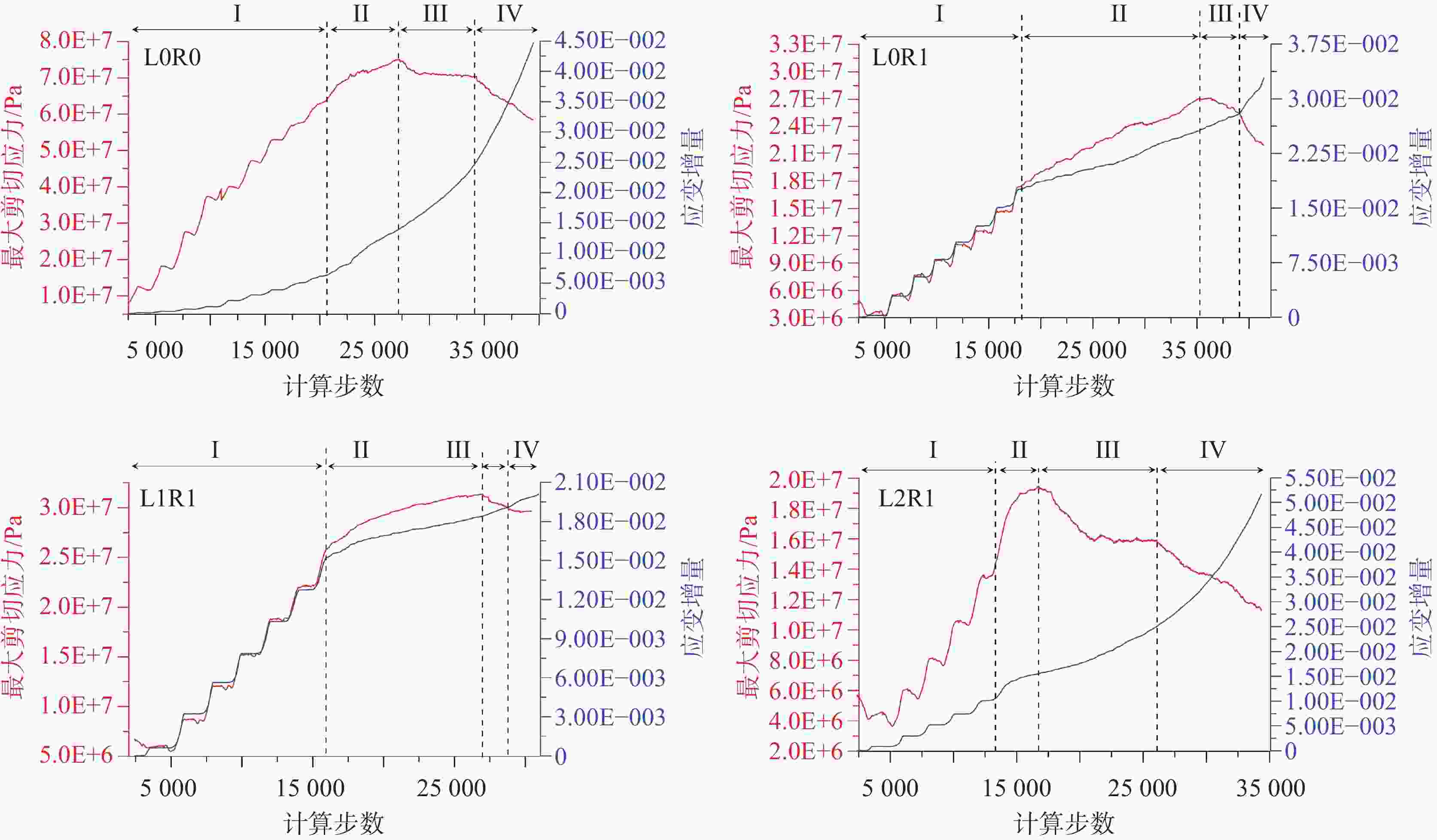

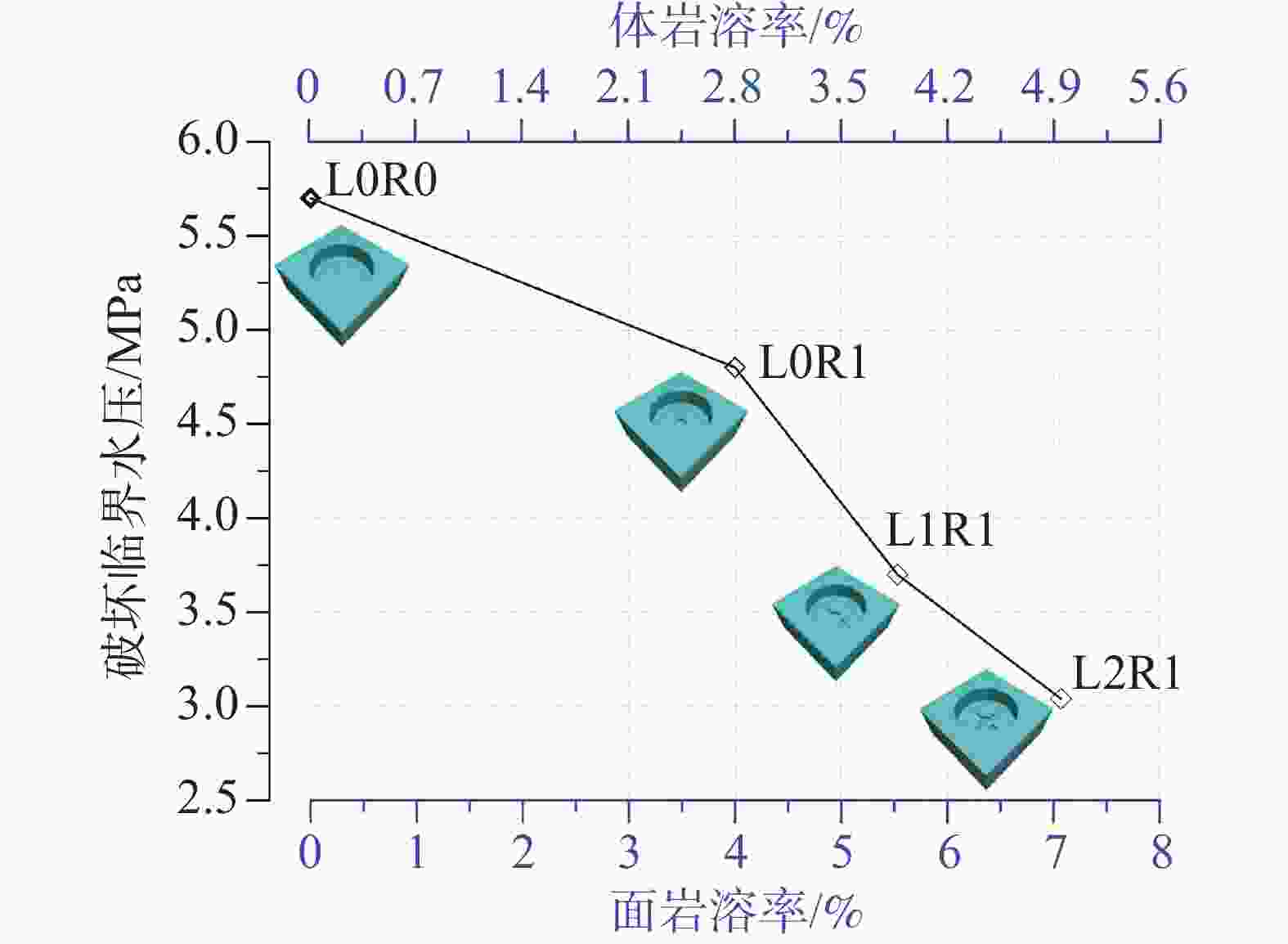

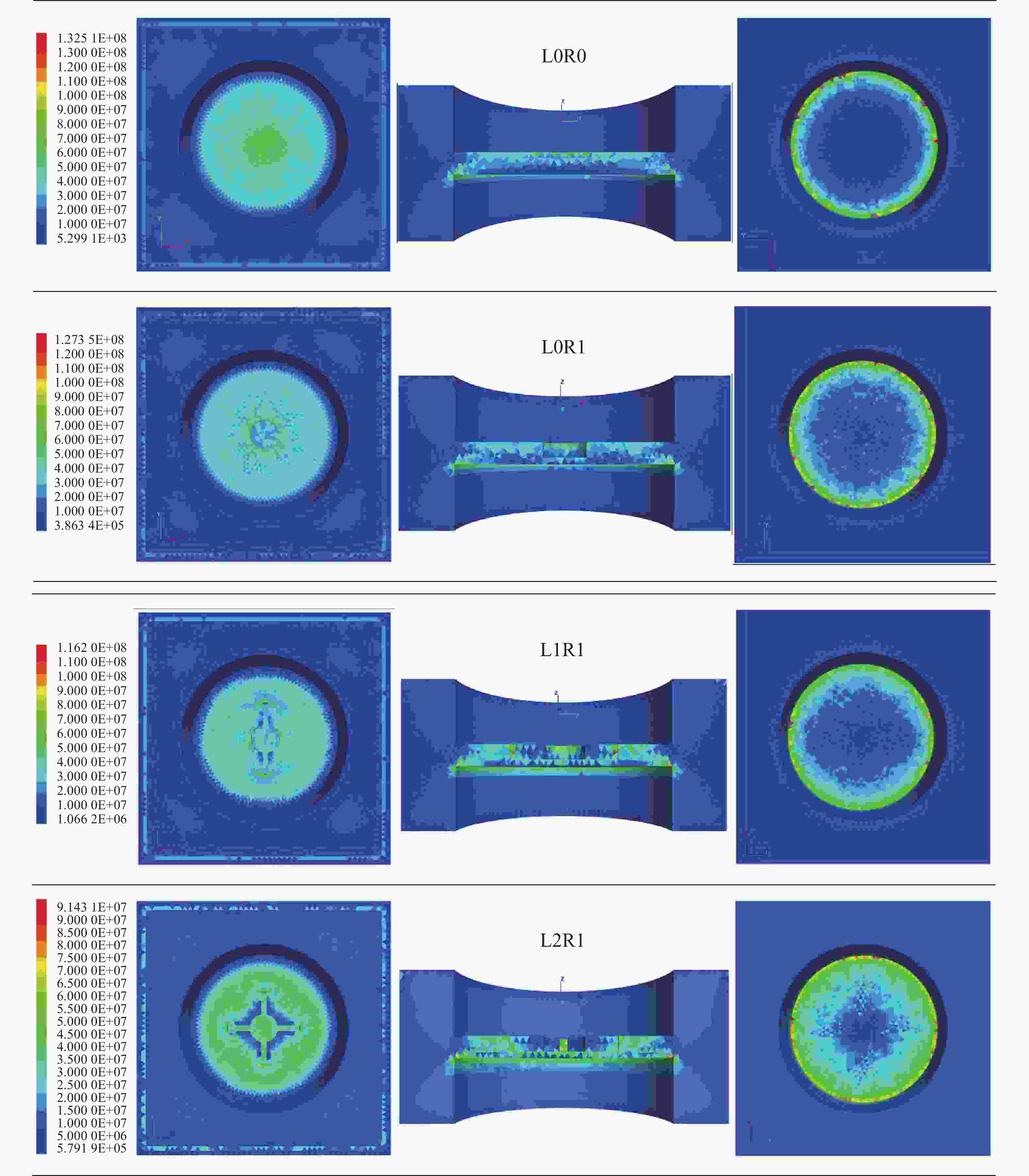

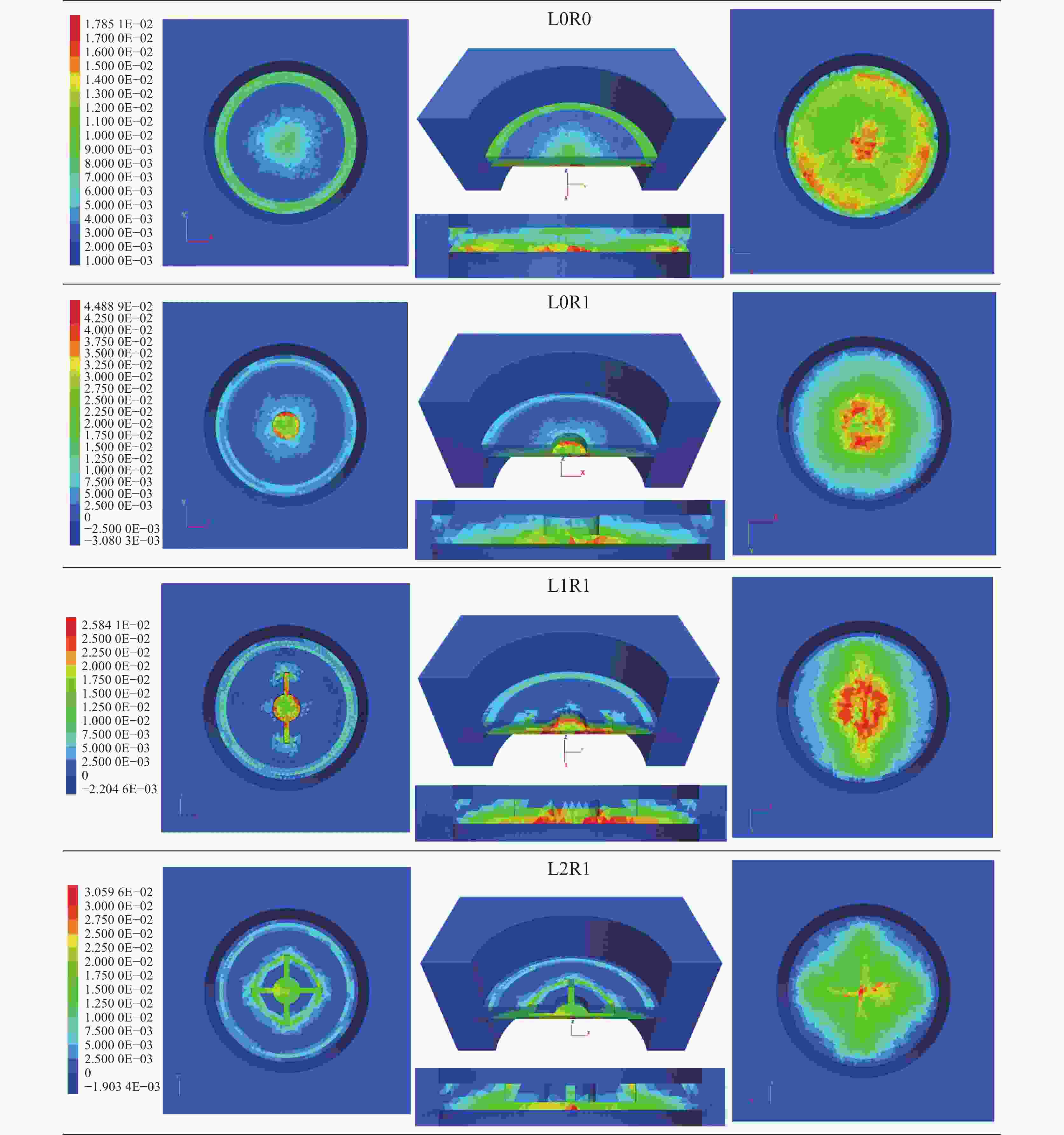

摘要: 岩溶区深埋巷道与围岩内水体之间的防突水岩层是阻隔地下水向巷道开挖临空面突涌的关键层。溶隙发育降低防突层岩体厚度和完整性,对防突层抵御地下水突涌造成不良影响。为研究溶隙发育对深埋灰岩防突层水力破坏特征的影响,在测定灰岩物理力学参数的基础上开展不同类型溶隙灰岩防突层在地应力和逐级水压作用下的数值研究。结果表明:(1)深埋溶隙灰岩防突层岩盘在高地应力和逐级水压加载下表现出四个变形破坏阶段:弹性变形阶段、塑性变形阶段、残余强度阶段和破坏阶段;(2)深埋灰岩防突层岩盘岩溶率越高,防突层岩盘水力破坏的临界水压力越小,研究获得了防突层岩盘破坏临界水压和岩溶率的关系曲线;(3)无溶隙发育的防突层岩盘在水压力作用下更容易在上表面周缘发生张拉破坏,在下表面周缘发生拉剪混合破坏,在下表面中心区域发生张拉破坏;(4)溶隙发育影响应力应变在防突岩盘内的分布,发育溶隙的防突层岩盘在水压力作用下更容易在溶隙带边缘与尖端处发生拉剪混合破坏,在岩盘下表面周缘发生压剪破坏,下表面中心区域发生张拉破坏;(5)多个邻近的溶隙尖端拉剪变形易相互贯通形成连续的拉剪破裂带。水压作用下防突岩盘因溶隙发育的不同可发生张拉破坏、拉剪破坏、压剪破坏或组合破坏。Abstract:

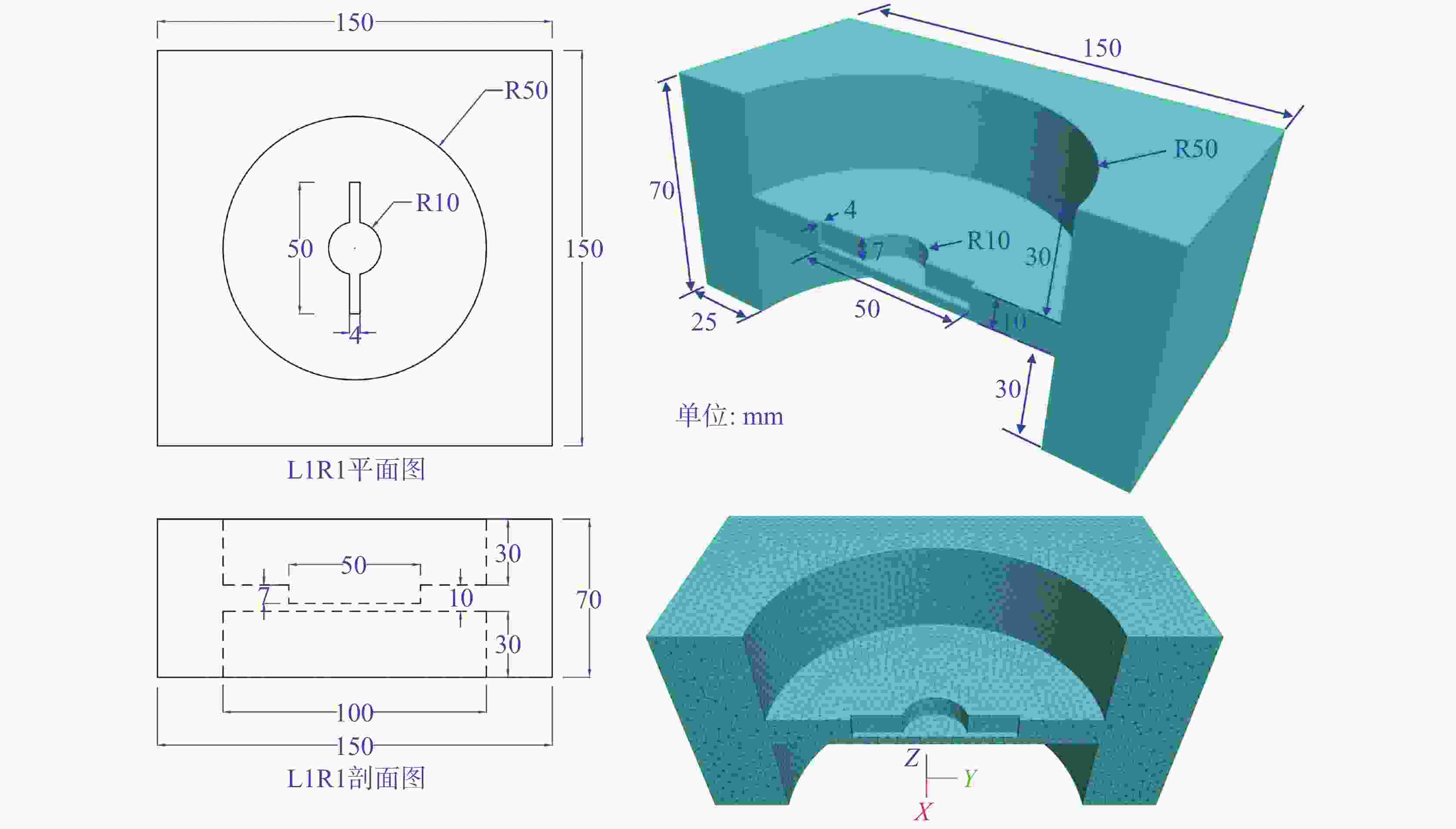

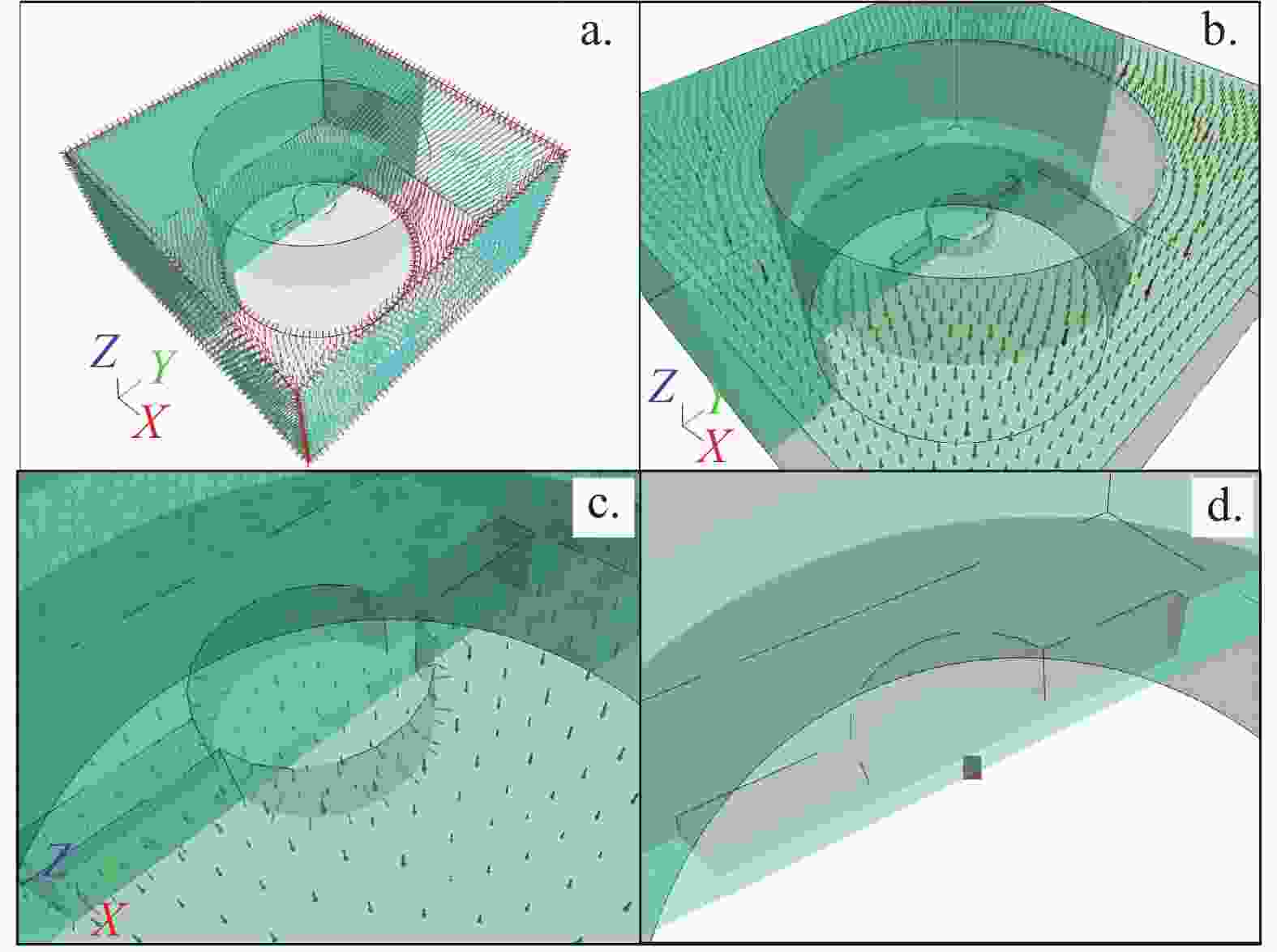

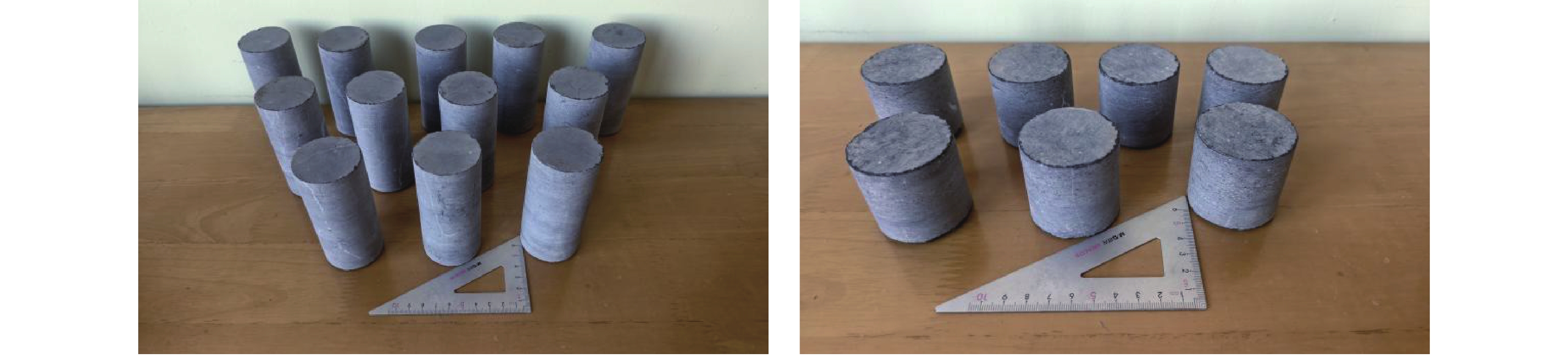

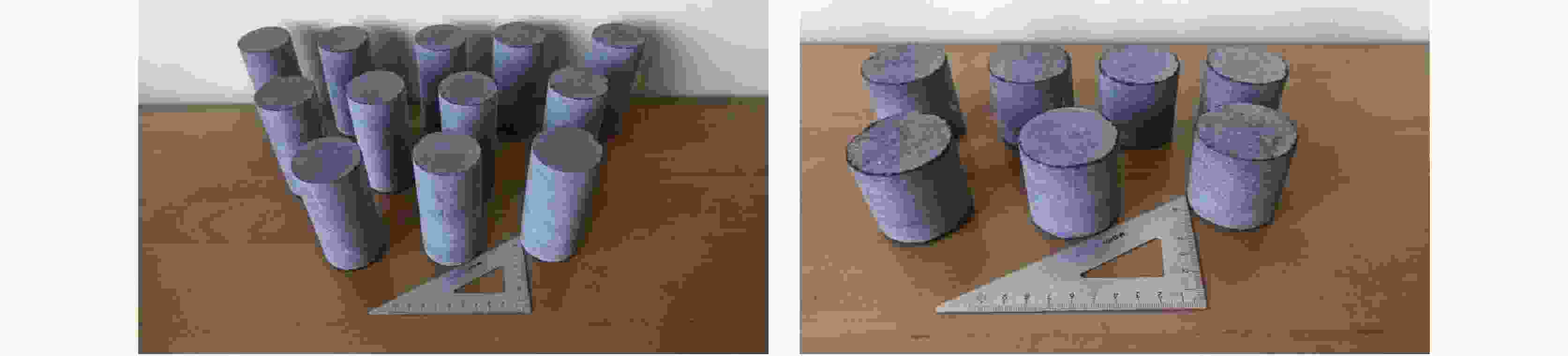

In tunnel engineering in karst areas, the tunnel mud and water inrush is one of the most common geological disasters. These events significantly impact tunnel construction, safe operation, and the safety of personnel and equipment, particularly in tunnels with large burial depths located in water-rich karst areas. Numerous factors affect tunnel mud and water inrush, including tunnel burial depth, groundwater pressure, surrounding rock stress, and the characteristics of the water inrush prevention layer-such as its thickness, karstification rate, fissure density, and mechanical strength. The water inrush prevention layer refers to the rock mass situated between the tunnel and groundwater, serving as the critical barrier that prevents groundwater from rushing toward the tunnel free face. The strength of the rock mass in this inrush prevention layer determines its capacity to resist groundwater pressure. Key factors affecting its overall strength include the thickness, karstification rate, fissure density, and mechanical strength of the prevention layer. The development of solution-fissures within this rock mass reduces its effective thickness and structural integrity, thereby diminishing its ability to withstand groundwater inrush toward the tunnel free face. To investigate the impact of the development of solution fissures in the limestone inrush prevention layer on its failure characteristics under hydraulic action in deep tunnels, limestone samples were collected, and tests were conducted to determine the physical and mechanical parameters of rock. The true density, tensile strength, elastic modulus, Poisson’s ratio, cohesion, and internal friction angle of the limestone material were obtained. Four different models for water inrush prevention were designed with the use of finite difference numerical simulation software. These models are square-rectangular in shape, with cylindrical holes cut opposite each other in the middle of the upper and lower surfaces, but not completely through. The remaining middle layer forms a disc-shaped batholite that serves as the water inrush prevention layer. Shallow circular holes and strip-shaped grooves are cut on the upper surface of this disc-shaped water inrush prevention layer, representing the solution fissures developed within the water inrush prevention layer. The circular holes and strip-shaped grooves differ among the four models, representing varying karstification rates. Based on this, the models were assigned the measured physical and mechanical parameters. Numerical simulations of the model for inrush prevention batholitel were conducted under fixed geostress at a depth of 1,000 m, with gradually increasing water pressure at an interval of 50 m after constraining the bottom and surrounding areas of the model. The maximum shear stress and maximum shear strain increment of the model’s force response are used as the criteria to analyze the characteristics of each stage of the model’s force deformation and failure, as well as the stress-strain distribution contour maps. The similarities and differences among the four models were compared. The research findings show that: (1)The deep-buried solution-fissured limestone used as inrush prevention batholitel undergoes four stages of deformation and failure under high geostress and gradually increasing water pressure: elastic deformation, plastic deformation, residual strength, and failure. (2) The higher the karstification rate of the deep-buried limestone used as an inrush prevention batholite, the lower the critical water pressure required to cause hydraulic failure of this batholite. A relationship curve between the critical water pressure for failure of the inrush prevention batholite and the karstification rate has been established. (3) Under the effect of water pressure, the inrush prevention batholite without solution fissures is more susceptible to tensile failure near the upper surface, mixed tensile-shear failure around the lower surface, and tensile failure in the central area of the lower surface. (4) The development of solution fissures affects the distribution of stress and strain within the inrush-prevention batholite. Under the effect of water pressure, the inrush-prevention batholite with solution fissures is more prone to mixed tensile and shear failure at the edges and tips of the solution fissure zones, compressive shear failure at the periphery of the lower surface of the batholite, and tensile failure in the central area of the lower surface. (5) Tensile and shear deformations at multiple adjacent solution fissure tips tend to interconnect, forming a continuous tensile and shear fracture zone. Under water pressure, the inrush prevention batholite may experience tensile failure, tensile-shear failure, compressive-shear failure, or a combination of these failure modes, depending on the development of the solution fissures. The research findings offer valuable insights into the deformation and failure characteristics of hydraulic fracturing in deeply buried rock formations, aiding in the prevention of water inrush. -

图 4 模型约束及应力加载示意图((a)模型四周及底部固定约束,(b)模型顶部施加地应力,(c)圆盘施加水压力,(d)监测点位置)

Figure 4. Schematic diagram of model constraints and stress loading (a) fixed constraints around and at the bottom of the model; (b) ground stress applied on the top of the model;(c) water pressure applied by the disc rock; (d) location of monitoring points

表 1 下石炭统尧云岭组泥质灰岩力学性能参数测试数据汇总表

Table 1. Summary of test data for mechanical property parameters of argillaceous limestone from the lower Carboniferous Yaoyunling Formation

巴西劈裂实验 破坏前 破坏后 抗拉强度/MPa 岩样1-1

3.91 单轴压缩实验 破坏前 破坏后 弹性模量/MPa 泊松比 岩样2-1

6.82 0.247 三轴压缩实验 破坏前 破坏后 黏聚力c /MPa 内摩擦角/φ 岩样3-1

14.69 49.13° 表 2 四个溶隙灰岩防突层模型

Table 2. Four models for solution-fissured limestone used as inrush prevention layer

模型编号 L0R0 L0R1 L1R1 L2R1 平面图

剖面图

立体图

面岩溶率/% 0 4.00 5.53 7.07 体岩溶率/% 0 2.80 3.87 4.95 -

[1] 储汉东. 岩溶隧道突水机理及防突层安全厚度研究[D]. 武汉: 中国地质大学, 2017.CHU Handong. Study on mechanism of water inrush and safety thickness of against-inrush layer in karst tunnel[D]. Wuhan: China University of Geosciences, 2017. [2] 李术才, 王康, 李利平, 周宗青, 石少帅, 柳尚. 岩溶隧道突水灾害形成机理及发展趋势[J]. 力学学报, 2017, 49(1): 22-30.LI Shucai, WANG Kang, LI Liping, ZHOU Zongging, SHI Shaoshuai, LIU Shang. Mechanical mechanism and development trend of water-inrush disasters in karst tunnels[J]. Chinese Journal of Theoretical and Applied Mechanics, 2017, 49(1): 22-30. [3] 浦海. 保水采煤的隔水关键层模型及力学分析[M]. 徐州: 中国矿业大学出版社, 2014.PU Hai. Key layer model and mechanical analysis of water retaining coal mining [M]. Xuzhou: China University of Mining and Technology Press, 2014. [4] 李利平. 高风险岩溶隧道突水灾变演化机理及其应用研究[D]. 济南: 山东大学, 2009.LI Liping. Research on the evolution mechanism and application of high risk karst tunnel water inrush disaster [D]. Jinan: Shandong University, 2009. [5] 高宗军, 郭健斌, 魏久传, 王敏. 水文地质学[M]. 徐州: 中国矿业大学出版社, 2011.GAO Zongjun, GUO Jianbin, WEI Jiuchuan, WANG Min. Hydrogeology[M]. Xuzhou: China University of Mining and Technology Press, 2011. [6] 戚启勋. 地球科学辞典[M]. 台北: 季风出版社, 1984.QI Qixun. Dictionary of earth sciences [M]. Taibei: Monsoon Press, 1984. [7] 李术才, 许振浩, 黄鑫, 林鹏, 赵晓成, 张庆松, 杨磊, 张霄, 孙怀风, 潘东东. 隧道突水突泥致灾构造分类、地质判识、孕灾模式与典型案例分析[J]. 岩石力学与工程学报, 2018, 37(5): 1041-1069.LI Shucai, XU Zhenhao, HUANG Xin, LIN Peng, ZHAO Xiaocheng, ZHANG Qingsong, YANG Lei, ZHANG Xiao, SUN Huaifeng, PAN Dongdong. Classification, geological identification, hazard mode and typical case studies of hazard-causing structures for water and mud inrush in tunnels[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(5): 1041-1069. [8] 肖喜, 赵晓彦, 张巨峰, 肖勇, 莫培. 岩溶隧道涌突水破坏模式分类及防突厚度研究[J]. 工程地质学报, 2022, 30(2): 459-474.XIAO Xi, ZHAO Xiaoyan, ZHANG Jufeng, XIAO Yong, MO Pei. Classification of water inrush failure mode and rock thickness for preventing water inrush in karst tunnels[J]. Journal of Engineering Geology, 2022, 30(2): 459-474. [9] 王绪. 岩溶隧道突水机理及防突安全厚度研究[D]. 成都: 西南交通大学, 2021.WANG Xu. Research on water burst mechanism and safety thickness of water proof-resistant slab of karst tunnel[D]. Chengdu: Southwest Jiaotong University, 2021. [10] 蒋腾飞. 爆破扰动下岩溶基坑防突层损伤失稳及最小安全厚度研究[D]. 大连: 大连海事大学, 2023.JIANG Tengfei. Study on the damage instability and the minimum safety thickness of the anti-outburst layer of karst foundation pit under blasting disturbance[D]. Dalian: Dalian Maritime University, 2023. [11] 杨超, 邹永木, 李磊, 钟祖良, 李亚朋. 深大断层破碎带隧道突水突泥机理研究[J]. 工业建筑, 2023, 53(3): 173-179.YANG Chao, ZOU Yongmu, LI Lei, ZHONG Zuliang, LI Yapeng. Research on mechanisms of water and mud inrush during tunnelling in deep and large fault fracture zones[J]. Industrial Construction, 2023, 53(3): 173-179. [12] 古继恒, 郭佳奇, 王二博, 陈帆, 李少华. 不同溶蚀程度灰岩巴西劈裂力学性能及能量演化特征[J]. 矿业研究与开发, 2024, 44(10): 115-124.GU Jiheng, GUO Jiaqi, WANG Erbo, CHEN Fan, LI Shaohua. Mechanical properties and energy evolution characteristics of Brazilian Spliting of limestone with different dissolution degrees[J]. Mining Research and Development, 2024, 44(10): 115-124. [13] SU Haijian, FENG Yujie, GUO Qingzhen, JING Hongwen, ZHU Wenxin. Model experimental study on the seepage and failure features of tunnel under wetting-drying alternation with increasing water pressure[J]. Geofluids, 2020(5): 1-11. [14] 舒宗运, 彭丁茂, 刘骏, 杜明泽. 隧道穿越溶洞及断层突水机理与防控对策研究[J]. 地下空间与工程学报, 2022, 18(S2): 993-1000.SHU Zongyun, PENG Dingmao, LIU Jun, DU Mingze. Study on water inrush mechanism and prevention and treatment measures of tunnel crossing karst area and fault zone[J]. Chinese Journal of Underground Space and Engineering, 2022, 18(S2): 993-1000. [15] ZHANG Weishe, JIAO Yuyong, ZHANG Guohua, ZHANG Xi, OU Guangzhao, LIN Zhiping. Analysis of the mechanism of water inrush geohazards in deep-buried tunnels under the complex geological environment of karst cave-fractured zone[J]. Journal of Earth Science, 2022, 33(5): 1204-1218. [16] 张为社. 岩溶地区深长隧洞突水机理研究[D]. 武汉: 中国地质大学, 2022.ZHANG Weishe. Study on the water inrush mechanism of deep and long tunnel in karst areas[D]. Wuhan: China University of Geosciences, 2022. [17] HUANG Zhen, ZENG Wei, WU Yun, LI Shijie, ZHAO Kui. Experimental investigation of fracture propagation and inrush characteristics in tunnel construction[J]. Natural Hazards, 2019, 97(1): 193-210. doi: 10.1007/s11069-019-03634-z [18] 黄震, 李仕杰, 赵奎, 吴云, 吴锐. 隧道完整型岩盘渗透破坏失稳机制流固耦合模型试验研究[J]. 应用基础与工程科学学报, 2019, 37(6): 1345-1356.HUANG Zhen, LI Shijie, ZHAO Kui, WU Yun, WU Rui. Liquid-solid coupling model test to investigate seepage failure mechanism of intact confining rocks of tunnels[J]. Journal of Basic Science and Engineering, 2019, 37(6): 1345-1356. [19] 郭佳奇, 钱源, 黄猛. 岩溶隧道防突岩层突水模拟分析[J]. 铁道建筑, 2019, 59(6): 77-80. doi: 10.3969/j.issn.1003-1995.2019.06.19GUO Jiaqi, QIAN Yuan, HUANG Meng. Simulation analysis of water inrush in outburst prevention rock layer of karst tunnel[J]. Railway Engineering, 2019, 59(6): 77-80. doi: 10.3969/j.issn.1003-1995.2019.06.19 [20] 邵长杰, 王 磊, 刘惠东, 崔永兴, 刘伟. 虎溪台隧道岩溶地下水涌水成因分析及涌水量预测[J]. 中国岩溶, 2025, 44(3): 477-487, 518. doi: 10.11932/karst20250303SHAO Changjie, WANG Lei, LIU Huidong, CUI Yongxing, LIU Wei. Genesis analysis of karst groundwater inrush and prediction of its water inflow in the Huxitai Tunnel[J]. Carsologica Sinica, 2025, 44(3): 477-487, 518. doi: 10.11932/karst20250303 [21] 郭佳奇, 王二博, 赖永标, 杨卫领. 岩溶隧道断续裂隙掌子面突水过程三维离散元分析[J]. 河南理工大学学报(自然科学版), 2023, 42(4): 156-161.GUO Jiaqi, WANG Erbo, LAI Yongbiao, YANG Weiling. Three-dimensional discrete element analysis of the water inrush process of the intermittent fissure tunnel face in a karst tunnel[J]. Journal of Henan Polytechnic University(Natural Science), 2023, 42(4): 156-161. [22] 张桥. 小三峡岩溶隧道围岩防突层安全厚度有限元分析[J]. 中国岩溶, 2020, 39(4): 614-621.ZHANG Qiao. Finite element analysis on safety thickness of the inrush prevention layer in rock beds of the small Three Gorges karst tunnel[J]. Carsologica Sinica, 2020, 39(4): 614-621. [23] 冯雪冬. 岩溶地区引水隧洞突水机理与围岩稳定性分析[D]. 武汉: 武汉工程大学, 2022.FENG Xuedong. Analysis of water burst mechanism and stability of surrounding rocks in karst area diversion tunnels[D]. Wuhan: Wuhan Institute of Technology, 2022. [24] 张珂峰. 前伏溶洞巷道开挖突水数值模拟研究[J]. 现代隧道技术, 2020, 57(3): 99-107.ZHANG Kefeng. Numerical simulation of water burst in roadway excavation with karst cave ahead[J]. Modern Tunnelling Technology, 2020, 57(3): 99-107. [25] 尚明源. 富水区隧道掌子面稳定性分析及防排水结构体系研究[D]. 成都: 西南交通大学, 2018.SHANG Mingyuan. Study on face stability and drainage and waterproof system of tunnel in water-rich strata[D]. Chengdu: Southwest Jiaotong University, 2018. [26] 陈泽龙, 崔江余, 王军, 杜涛, 李迁. 富水断层带隧道突水突泥的临界判据[J]. 铁道建筑, 2020, 60(11): 53-63. doi: 10.3969/j.issn.1003-1995.2020.11.13CHEN Zelong, CUI Jiangyu, WANG Jun, DU Tao, LI Qian. Critical criterion for water inrush and mud gushing of tunnel in water-rich fault zone[J]. Railway Engineering, 2020, 60(11): 53-63. doi: 10.3969/j.issn.1003-1995.2020.11.13 [27] 李亚鑫. 岩溶隧道释能降压防突层安全厚度及其施工方案优化研究[D]. 成都: 四川农业大学, 2022.LI Yaxin. Study on the safety thickness and construction scheme optimization of energy release depressurization and outburst prevention layer in Karst tunnel[D]. Chengdu: Sichuan Agricultural University, 2022. [28] 李利平, 朱宇泽, 周宗青, 石少帅, 陈雨雪, 屠文锋. 隧道突涌水灾害防突厚度计算方法及适用性评价[J]. 岩土力学, 2020, 41(S1): 41-50.LI Liping, ZHU Yuze, ZHOU Zongqing, SHI Shaoshuai, CHEN Yuxue, TU Wenfeng. Calculation methods of rock thickness for preventing water inrush in tunnels and their applicability evaluation[J]. Rock and Soil Mechanics, 2020, 41(S1): 41-50. [29] ZHANG Lewen, WU Jing, ZHANG Xiangyu. Mechanism of water inrush from the tunnel face induced by fault and its application[J]. Journal of Central South University, 2023, 30(3): 934-946. doi: 10.1007/s11771-023-5283-y [30] 李鹏飞, 刘宏翔, 赵勇, 刘建友, 王帆. 隧道穿越断层破碎带防突水最小安全厚度及其影响因素[J]. 隧道与地下工程灾害防治, 2020, 2(3): 77-84.LI Pengfei, LIU Hongxiang, ZHAO Yong, LIU Jianyou, WANG Fan. The minimum safe thickness of tunSnel passing through fault fracture zone and its influencing factors[J]. Hazard Control in Tunnelling and Underground Engineering, 2020, 2(3): 77-84. [31] 秦鹏飞, 赵亚敏, 宋 梦, 王文菁. 隧道突泥涌水致灾机理及防控技术研究[J]. 中国岩溶, 2025, 44(2): 359-369. doi: 10.11932/karst20250213QIN Pengfei, ZHAO Yamin, SONG Meng, WANG Wenjing. Research on the mechanism and prevention technologies of mud and water inrush disasters in tunnels[J]. Carsologica Sinica, 2025, 44(2): 359-369. doi: 10.11932/karst20250213 [32] 孟凡树, 王迎超, 焦庆磊, 王月明, 李朝阳. 断层破碎带突水最小安全厚度的筒仓理论分析[J]. 哈尔滨工业大学学报, 2020, 52(2): 89-95. doi: 10.11918/201810155MENG Fanshu, WANG Yingchao, JIAO Qinglei, WANG Yueming, LI Zhaoyang. Analysis of the minimum safe thickness of water inrush in fault fracture zone based on the silo theory[J]. Journal of Harbin Institute of Technology, 2020, 52(2): 89-95. doi: 10.11918/201810155 [33] 安艳军, 乔栋磊, 万创业, 赵旭, 陈诺, 李文杰. 深埋隧道溶洞岩体防突层安全厚度研究[J]. 低温建筑技术, 2024, 46(2): 115-118.AN Yanjun, QIAO Donglei, WAN Chuangye, ZHAO Xu, Chen Nuo, LI Wenjie. Study on the minimum safe thickness of water-proof rock mass in karst cave of deep buried tunnel[J]. Low Temperature Architecture Technology, 2024, 46(2): 115-118. [34] 周小龙, 李澳, 冯雪冬. 岩溶地区隧道围岩临界防突厚度数值分析[J]. 武汉工程大学学报, 2024, 46(4): 452-459.ZHOU Xiaolong, LI Ao, FENG Xuedong. Numerical analysis of thickness of critical outburst prevention layer of peripheral rock in karst tunnel[J]. Journal of Wuhan Institute of Technology, 2024, 46(4): 452-459. [35] 李冉. 富水岩溶区隧道施工围岩稳定性与超前支护机理研究[D]. 张家口: 河北建筑工程学院, 2023.LI Ran. Study on stability and advance support mechanism of surrounding rock in tunnel construction in water-rich karst area[D]. Zhangjiakou: Hebei University of Architecture, 2023. [36] 武世燕. 岩溶区隧道隔水岩盘安全厚度预测[J]. 隧道建设(中英文), 2021, 41(12): 2083-2092.WU Shiyan. Prediction of safe thickness of water-insulating rock disks in tunnels in karst areas[J]. Tunnel Construction, 2021, 41(12): 2083-2092. [37] 王万锋, 杨永泰, 陆钰铨, 赵楚军, 崔鹏杰, 邱军领. 喀斯特地貌区隧道与隐伏充填溶洞临界安全距离分析[J]. 中国岩溶, 2023, 42(6): 1282-1293. doi: 10.11932/karst20230610WANG Wanfeng, YANG Yongtai, LU Yuquan, ZHAO Chujun, CUI Pengjie, QIU Junling. Analysis of critical safety distance between tunnel and concealing filled karst cave in the karst area[J]. Carsologica Sinica, 2023, 42(6): 1282-1293. doi: 10.11932/karst20230610 -

下载:

下载: