Numerical simulation of bearing mechanism of steel casing group in complex karst area

-

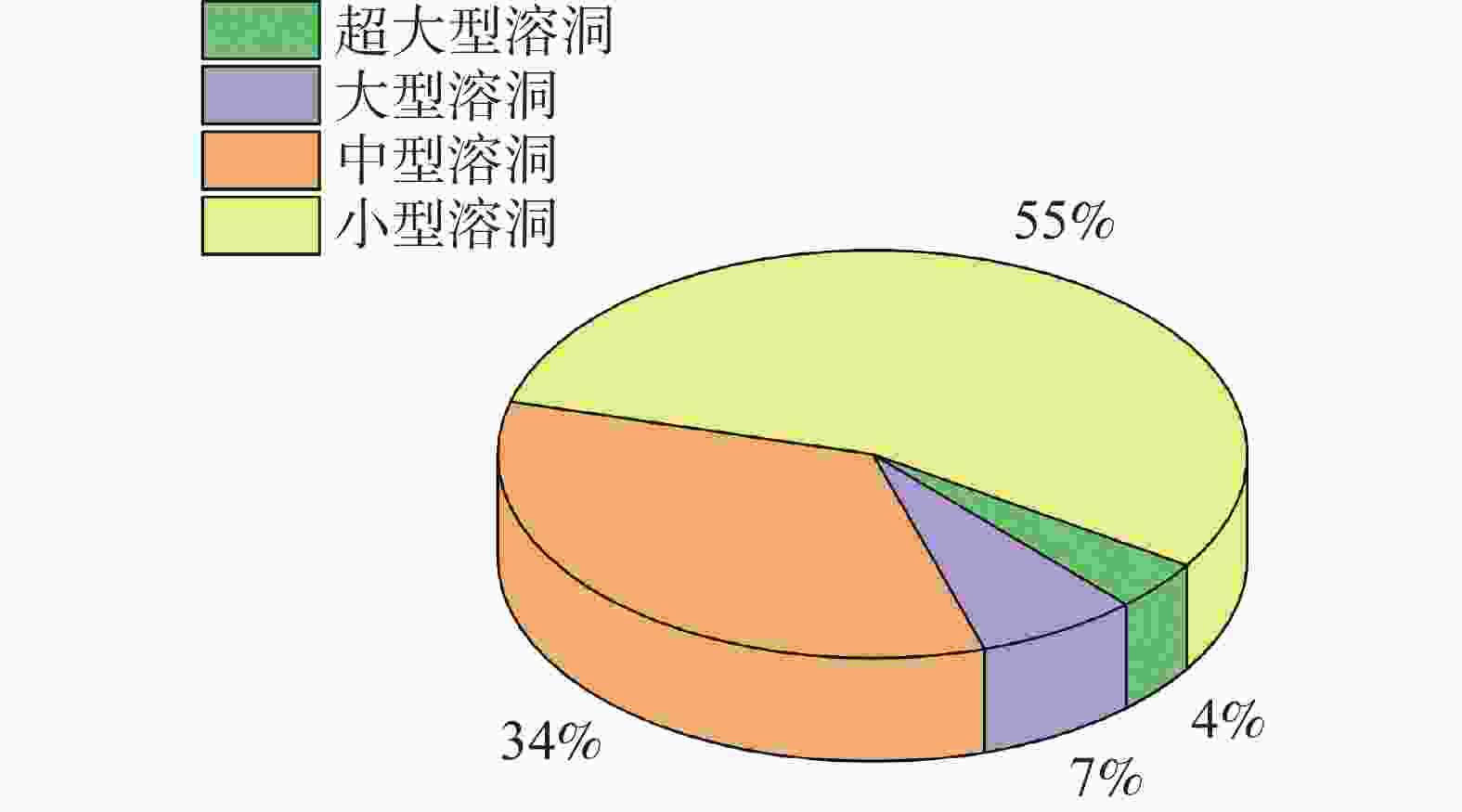

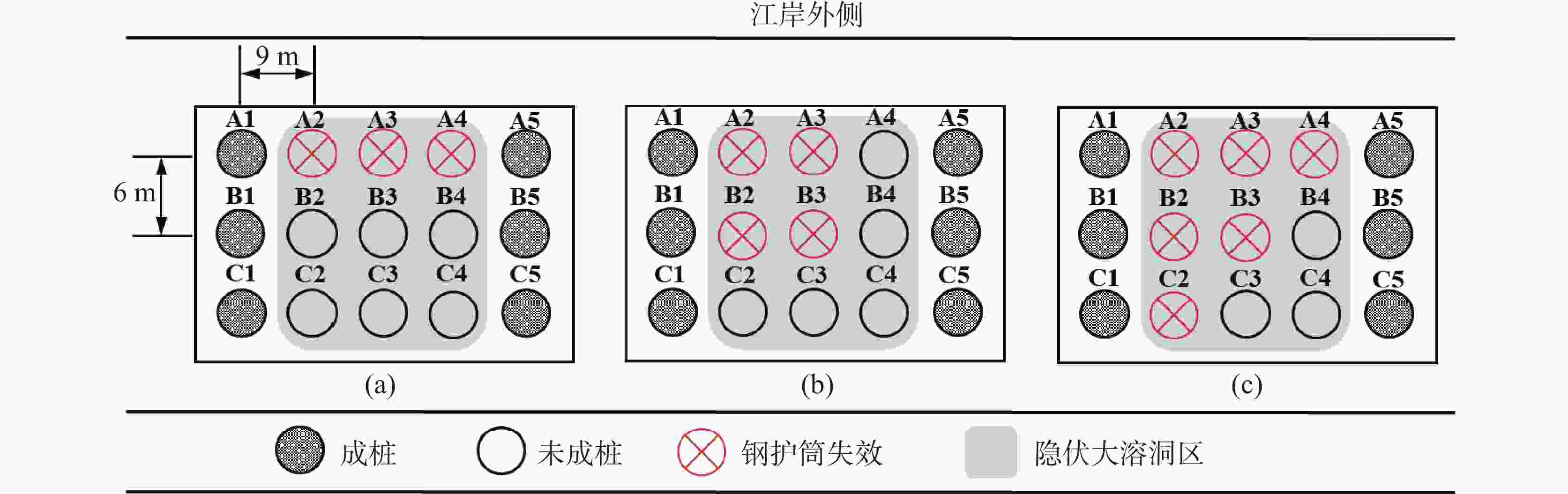

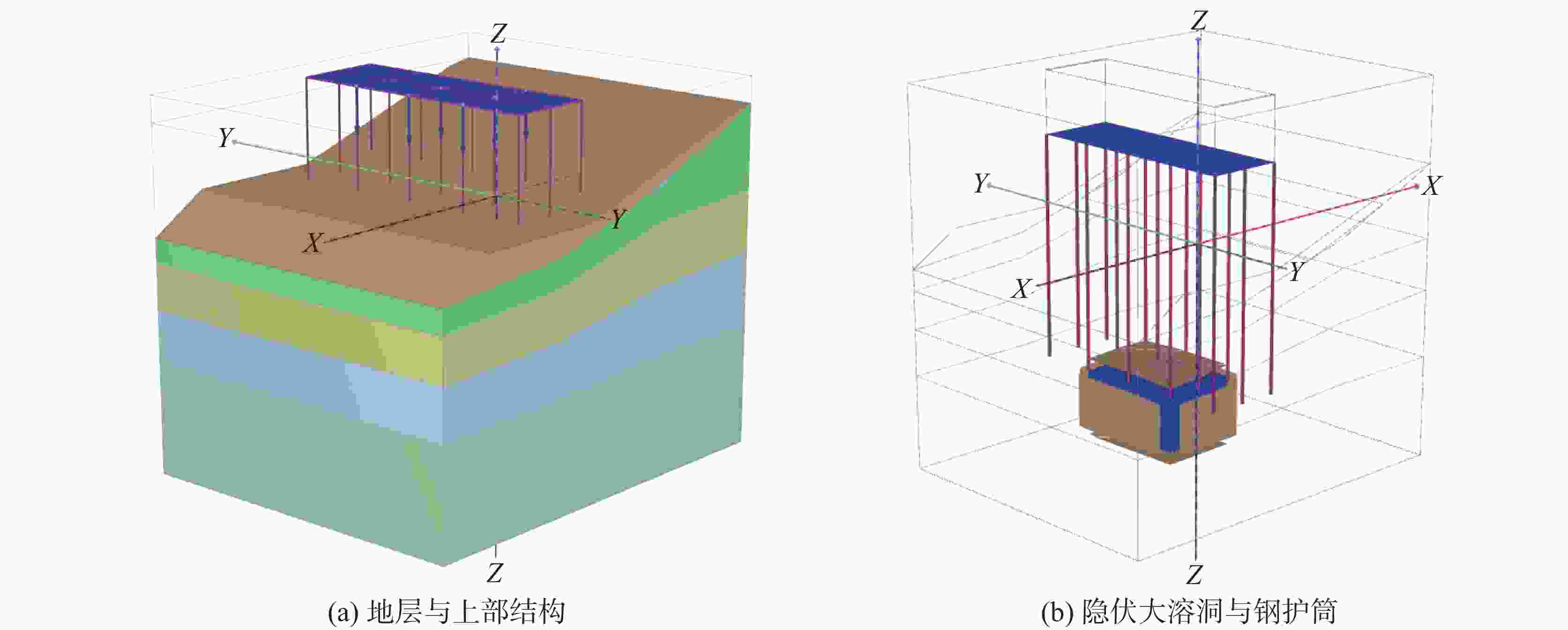

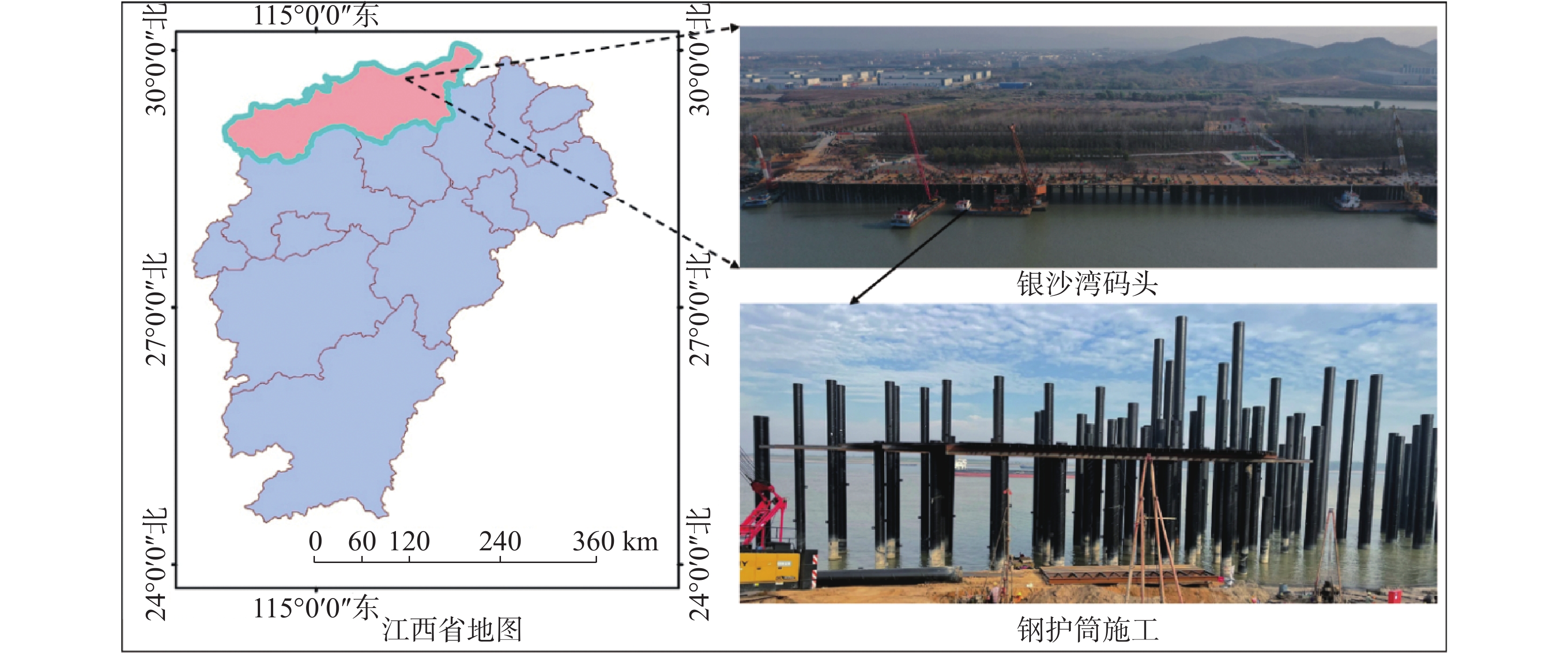

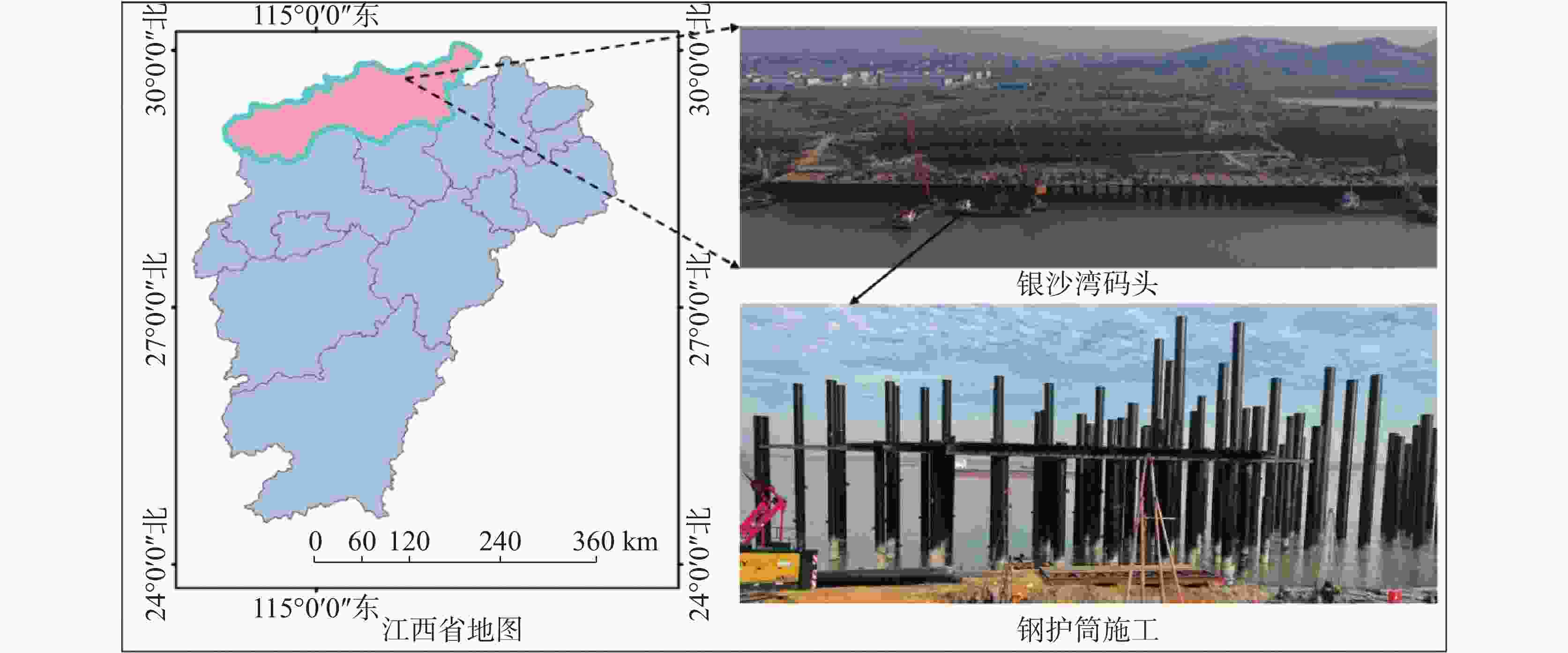

摘要: 岩溶区桩基施工过程中,隐伏溶洞空间分布的不确定性导致施工过程风险性提高,尤其是搭设钢护筒时,结构荷载超过钢护筒侧摩阻力,可导致钢护筒下沉对施工工作面带来安全风险。文章以江西九江银沙湾复杂岩溶区桩基施工工程为例,模拟研究了岩溶区钢护筒群的承载特性。结果表明:整个施工区域岩溶非常发育,溶洞占比为76.2%,溶洞的最大高度为17.3 m,且存在大溶洞串洞现象。按照大溶洞区空间分布特点,钢护筒群下沉模式分为三种,三角形区钢护筒群下沉、矩形区钢护筒群下沉和单排型钢护筒群下沉。提出预设指定位移来反分析钢护筒群下沉过程的模拟方法,模拟结果显示,隐伏大溶洞区施工方式应该按照外侧优先成桩,内侧选点成桩方式进行。Abstract:

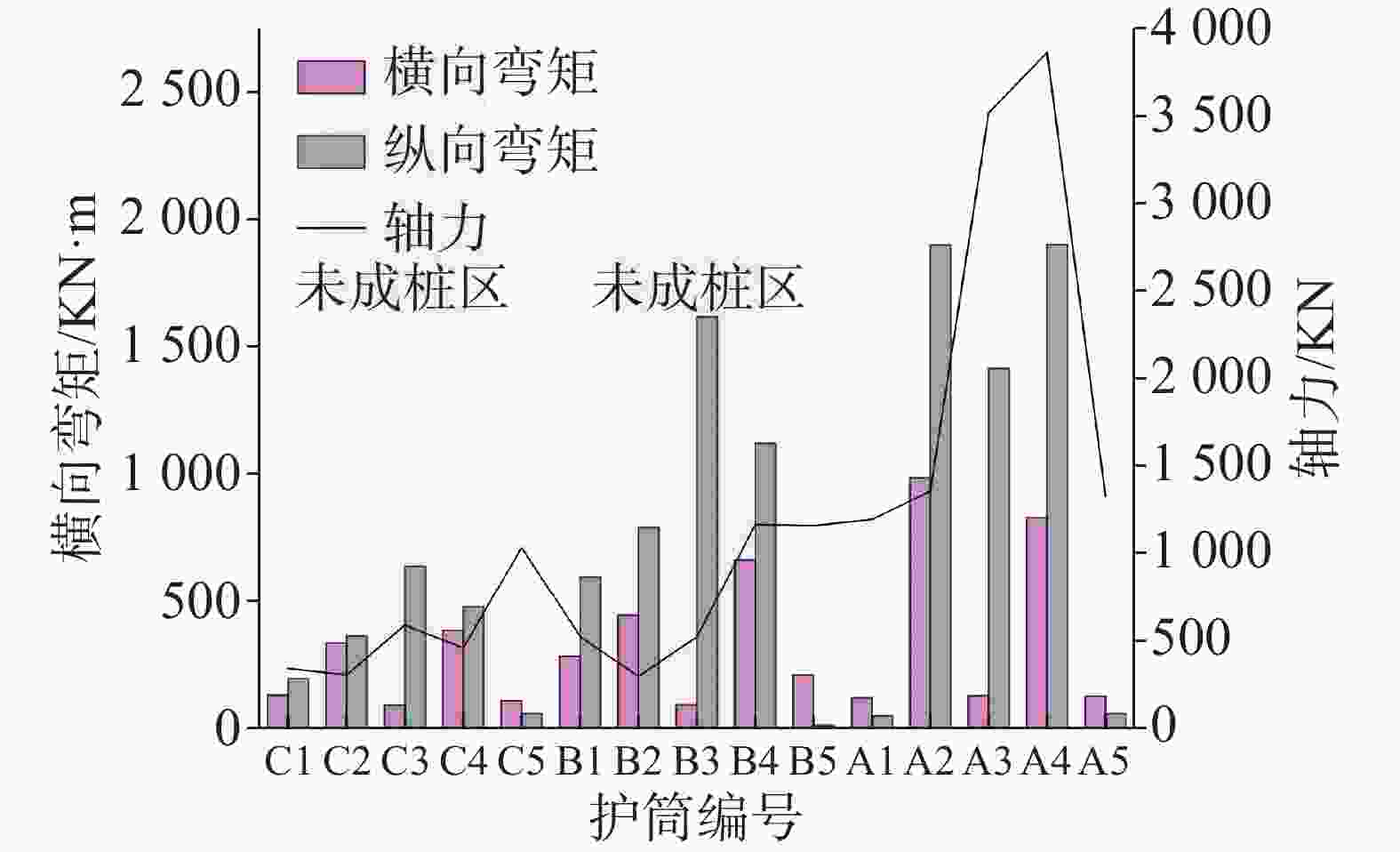

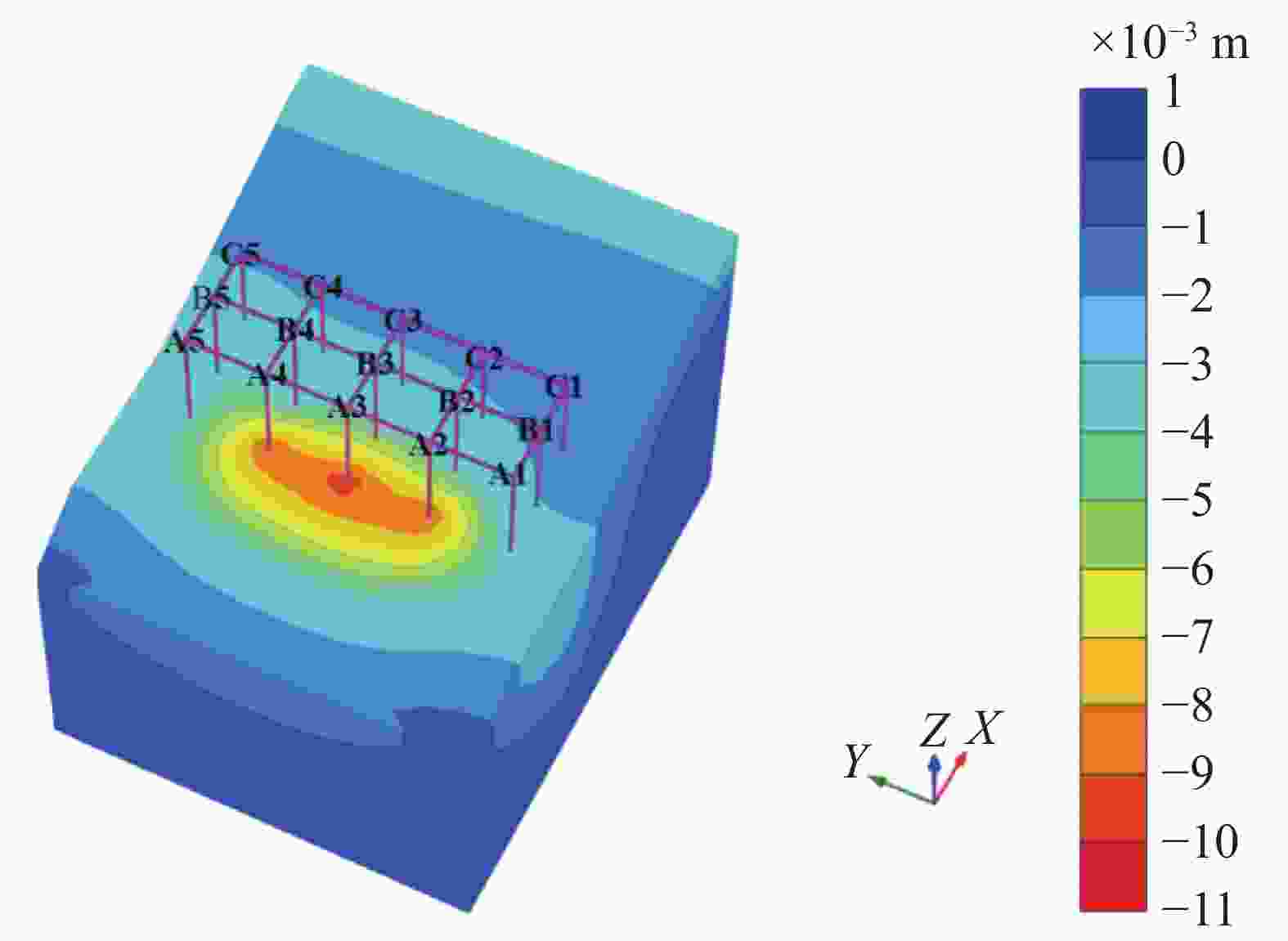

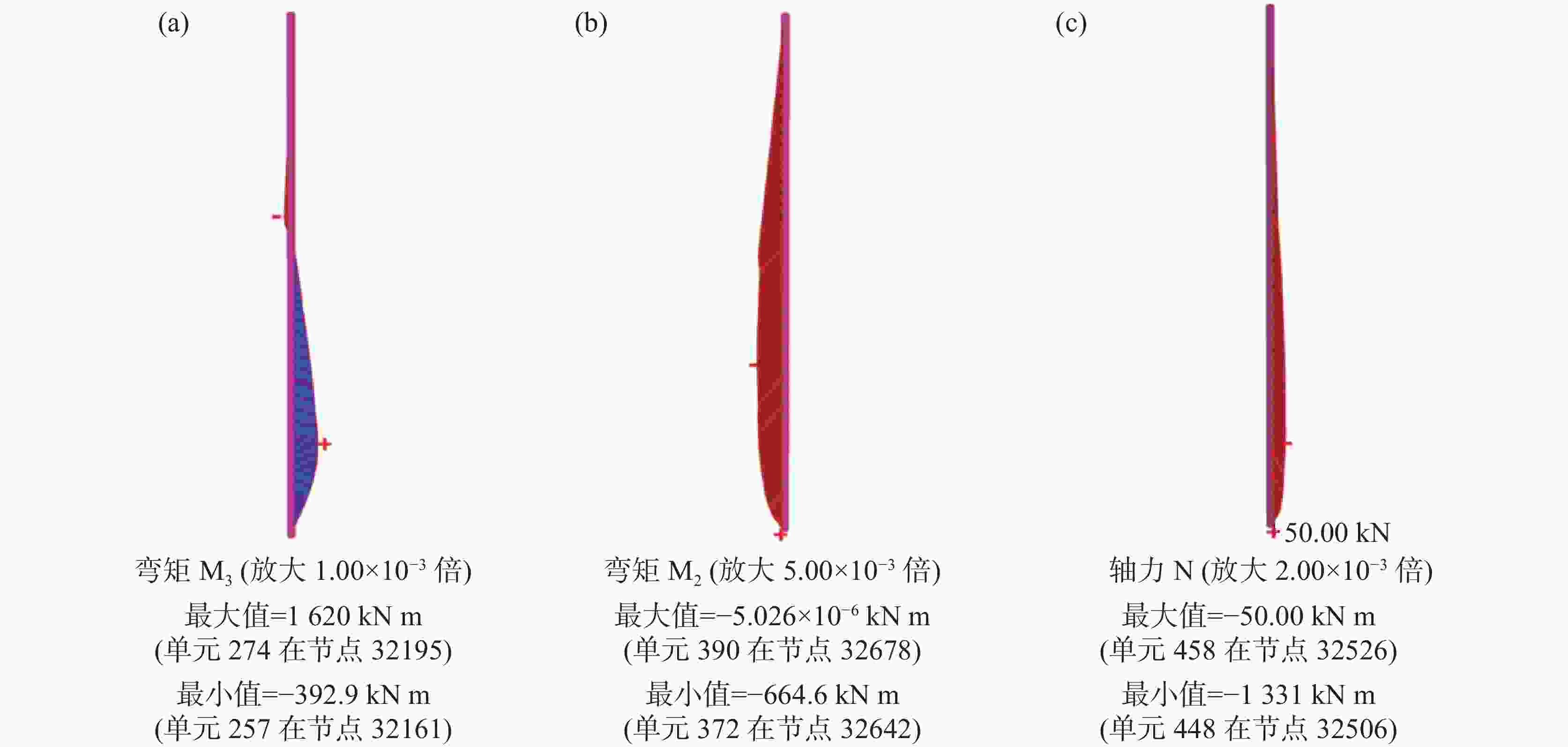

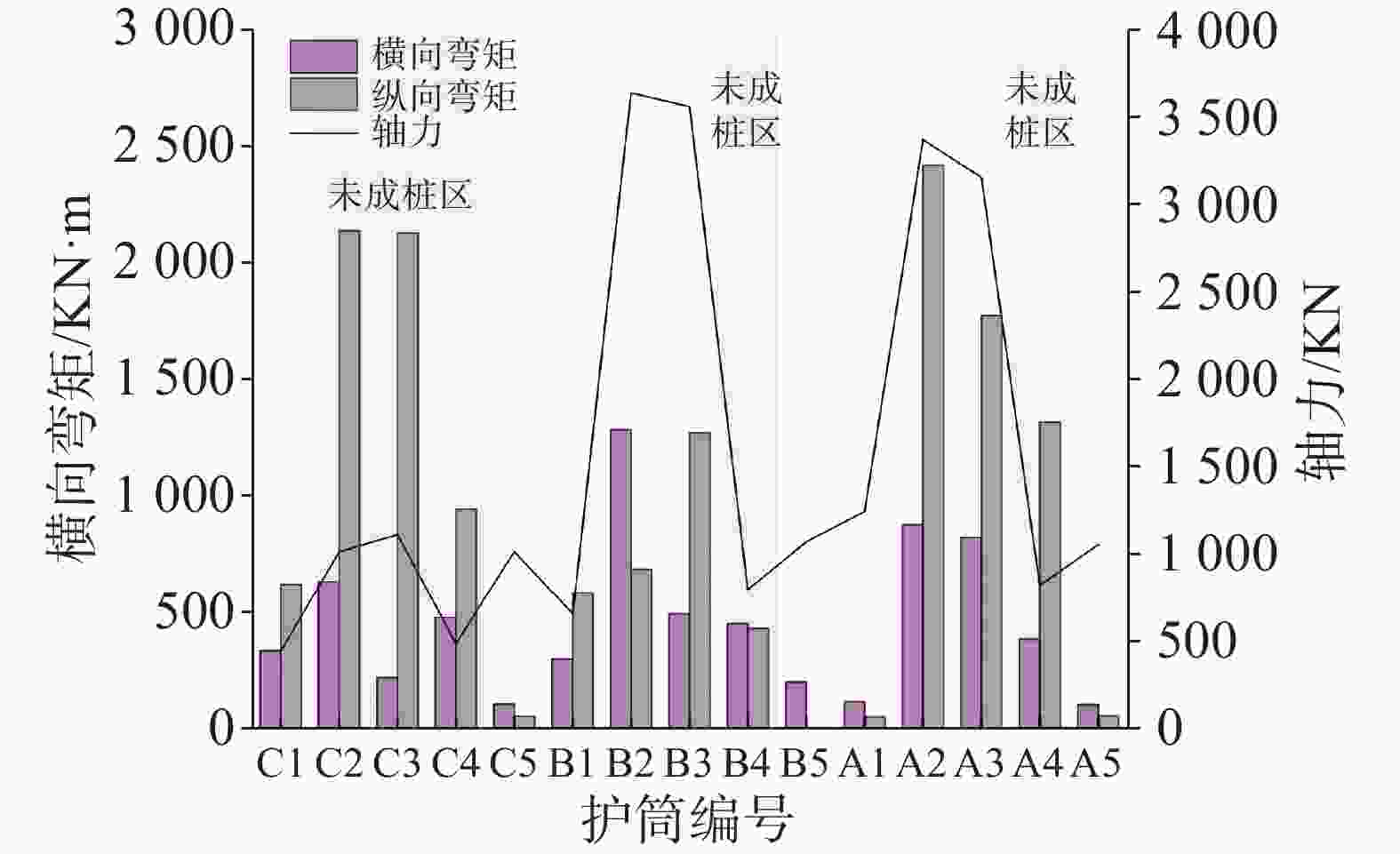

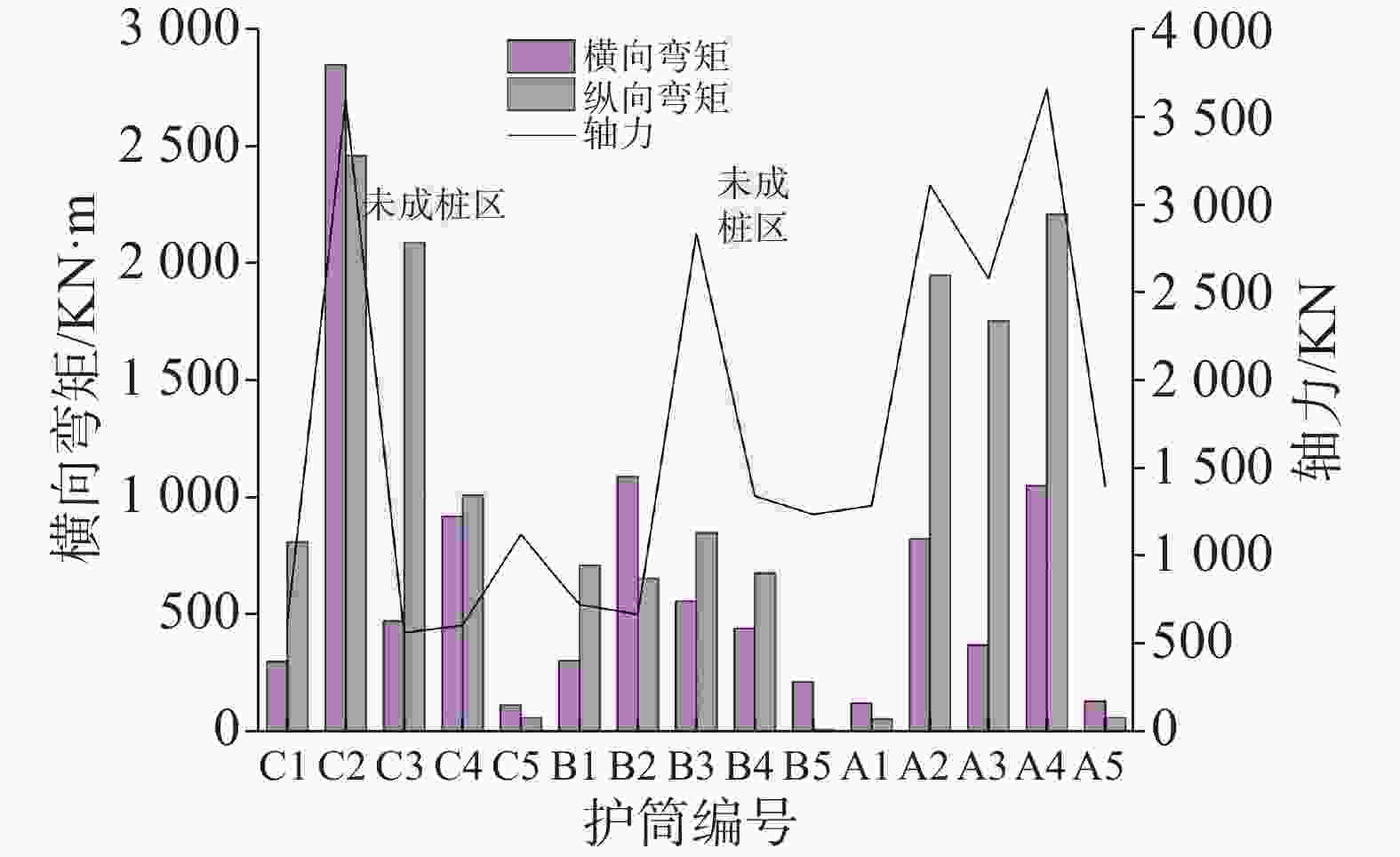

The construction of pile foundations in karst areas presents unique challenges due to the unpredictable spatial distribution of underground cavities, which may significantly increase the associated risk of such projects. Karst topography is characterized by the presence of soluble rocks, such as limestone, which have been gradually dissolved by groundwater, resulting in the formation of crevices and caves. This geological feature poses significant difficulties for engineers, as the unpredictability of these subsurface formations can lead to complications during construction, especially when steel casings are installed for pile foundations. In karst areas, the risk to the construction process tends to be exacerbated by the possibility of encountering covered caves. When steel casings are built, the structural load may exceed the side friction of the casings, potentially causing them to sink. This situation escalates the construction risks, making the project more complex and challenging. The project for pile foundation construction in the complex karst area of Yinshawan, Jiujiang, Jiangxi (hereinafter referred to as the Yinshawan Project), exemplifies such challenges associated with this type of environment. This area is highly karstic, with caves constituting 76.2% of the karst topography and the largest cave reaching a height of 17.3 m. These characteristics require an improved approach to steel casing construction to prevent sinking and collapse. To solve these issues, this study introduces a three-dimensional numerical model that incorporates the presence of caves, informed by preliminary drilling data and exploration conditions specific to the Yinshawan Project. This model is a critical tool for understanding the subsidence behavior of steel casings in karst areas. This study classifies subsidence patterns into three distinct categories: single-row steel casing groups, triangular steel casing groups, and rectangular steel casing groups. It examines the mechanics of steel casing subsidence in areas affected by karst development. The method involves simulating specified displacements to retroactively analyze the sinking process of steel casing groups. Through numerical simulations, this study examined the load-bearing characteristics of steel casing groups in various sinking modes. The findings reveal that the sinking modes differed significantly in terms of the maximum longitudinal and transverse bending moments experienced by the casings. For instance, in the single-row steel casing group, the maximum longitudinal bending moment was found to be 1,620 kN·m, while the maximum transverse bending moment was 664.6 kN·m. In the sinking mode of the steel casing group within the rectangular area, the maximum transverse bending moment in the non-sinking steel casing was 637.8 kN·m, and the maximum longitudinal bending moment was 2,144 kN·m; both of these values were found in the same steel casing. In the sinking mode of the triangular steel casing group, the maximum longitudinal bending moment in the non-sinking steel casing was 2,090 kN·m, and the maximum transverse bending moment was 922.2 kN·m. The study offers detailed analysis of each sinking mode, highlighting the stress characteristics and potential risks of subsidence. Given these risks and the specific stress characteristics identified through simulations, a construction method in areas with significant covered caves, such as the project site in Yinshawan, should be prioritized. This method should focus on peripheral piling while selectively placing piles in the interior. This study provides valuable insights into the field of geotechnical engineering, offering guidance for future projects in similarly challenging environments. -

Key words:

- karst area /

- steel casing /

- bearing characteristics /

- numerical simulation /

- failure analysis

-

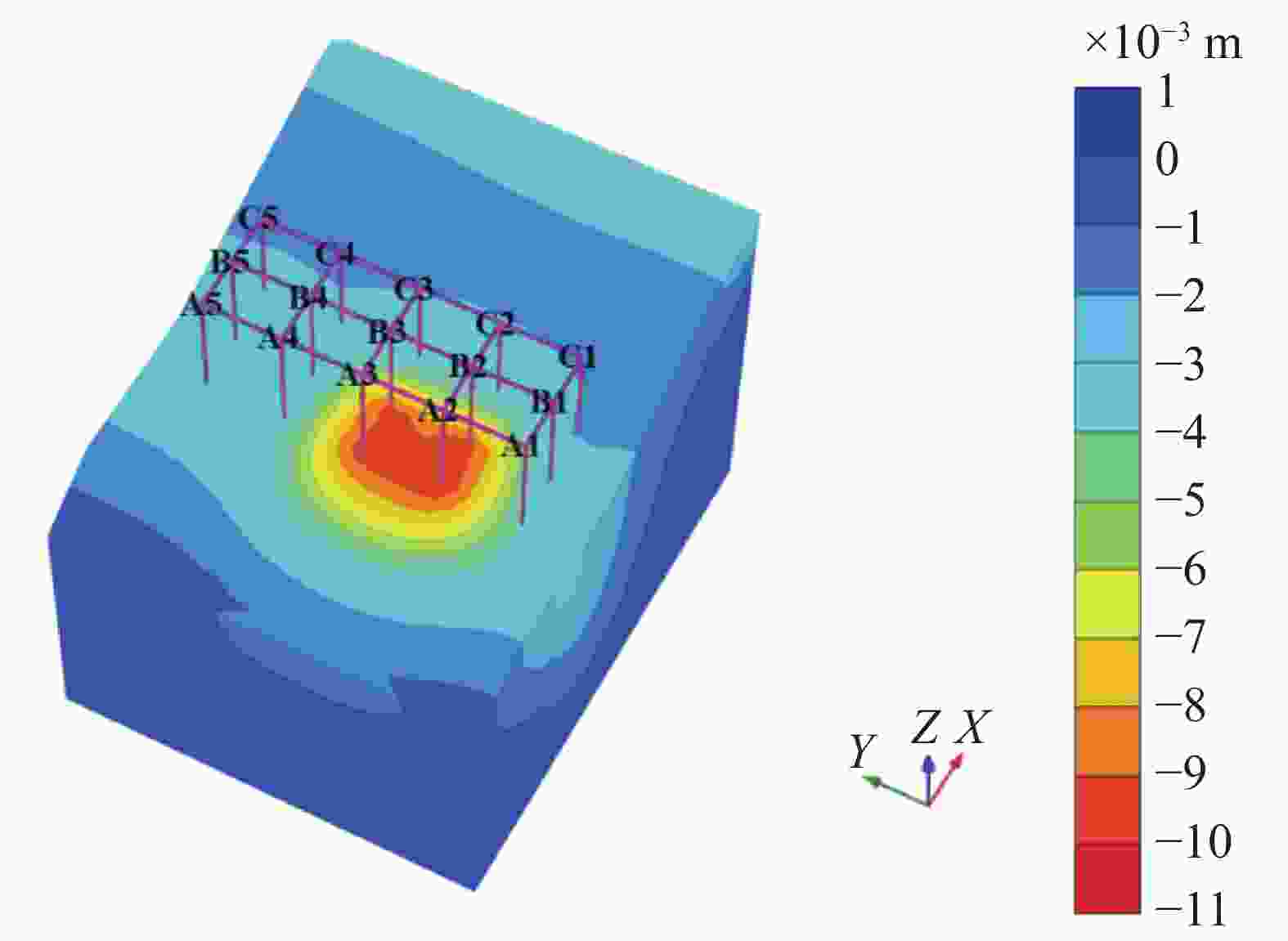

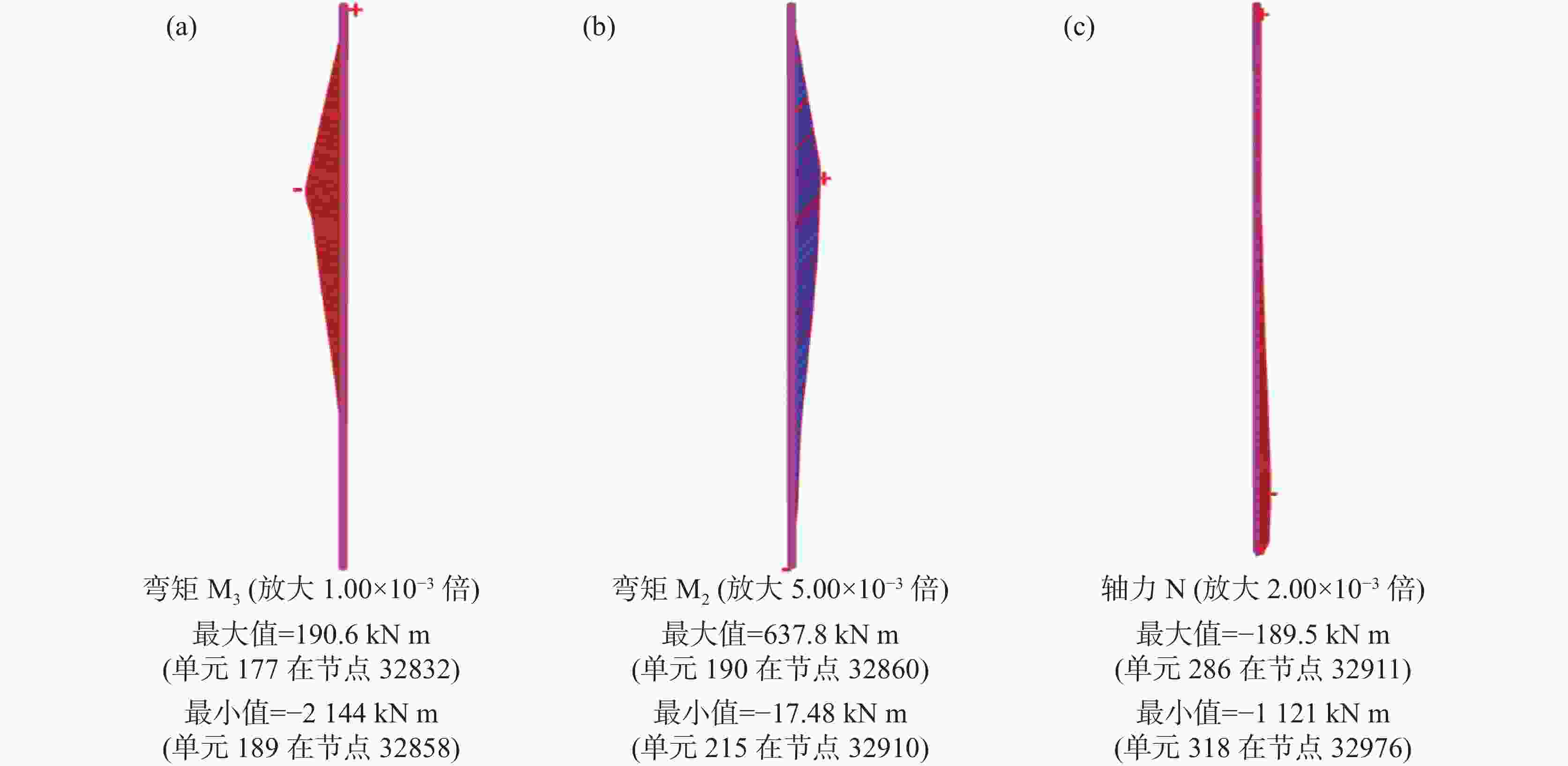

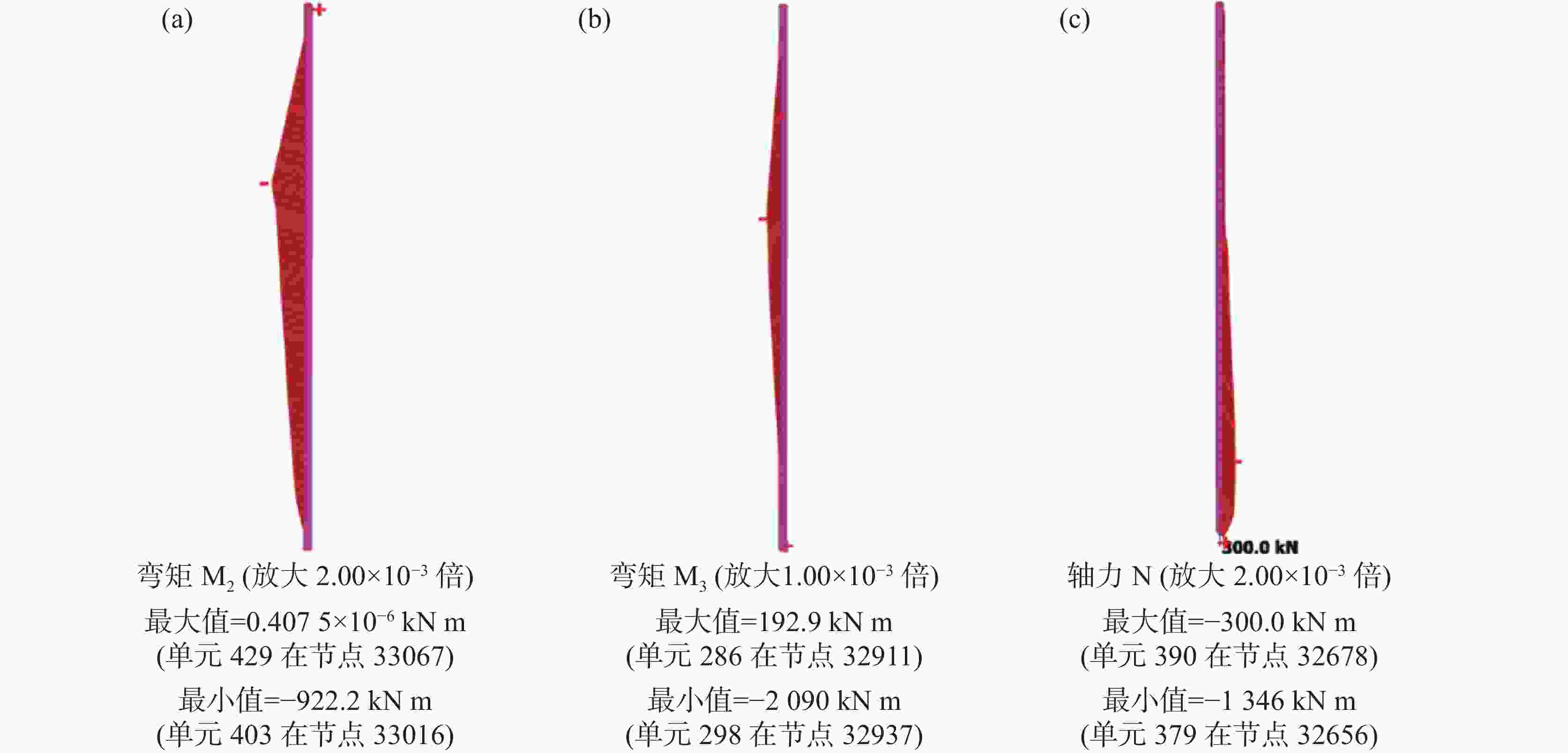

图 9 未成桩区弯矩与轴力最大值点

注:(a)纵向弯矩点:钢护筒B3,(b)横向弯矩点:钢护筒B4, (c)轴力点:钢护筒B4。

Figure 9. Maximum point of bending moment and axial force in the unformed pile area

Note: (a) Point of longitudinal bending moment point: steel casing B3; (b) Point of transverse bending moment point: steel casing B4; (c) Point of axial force: steel casing B4.

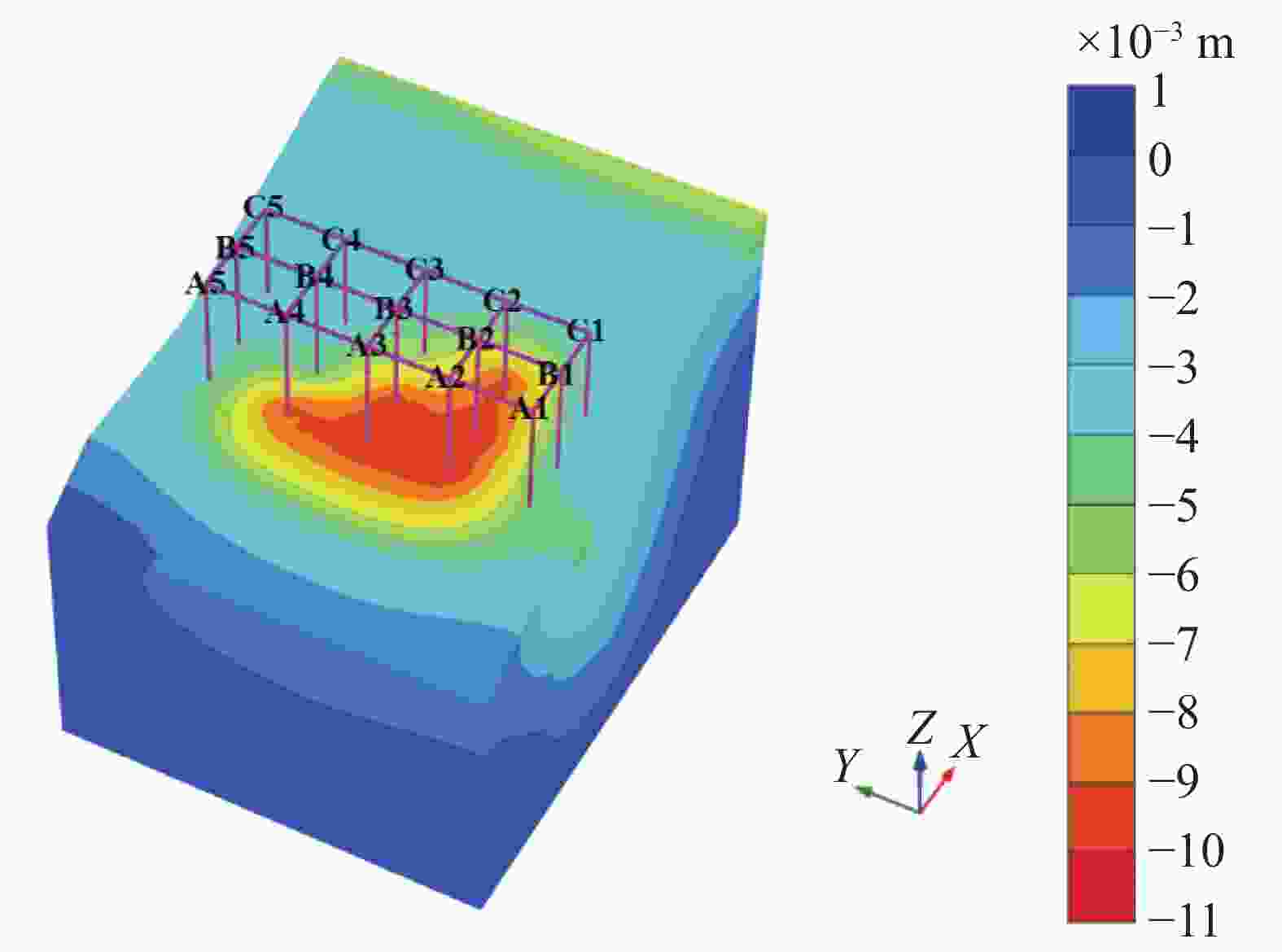

图 12 未成桩区弯矩与轴力最大值点

注:(a)纵向弯矩点:钢护筒C2,(b)横向弯矩点:钢护筒C2, (c)轴力点:钢护筒C3。

Figure 12. Maximum point of bending moment and axial force in the unformed pile area

Note: (a) Point of longitudinal bending moment: steel casing C2; (b)Point of transverse bending moment point: steel casing C2; (c) Point of axial force point: steel casing C3.

图 15 未成桩区弯矩与轴力最大值点

注:(a)纵向弯矩点:钢护筒C3, (b)横向弯矩点:钢护筒C4,(c)轴力点:钢护筒B4。

Figure 15. Maximum points of bending moment and axial force in the unformed pile area

Note: (a) Point of longitudinal bending moment: steel casing C3; (b) Point of transverse bending moment: steel casing C4; (c) Point of axial force : steel casing B4.

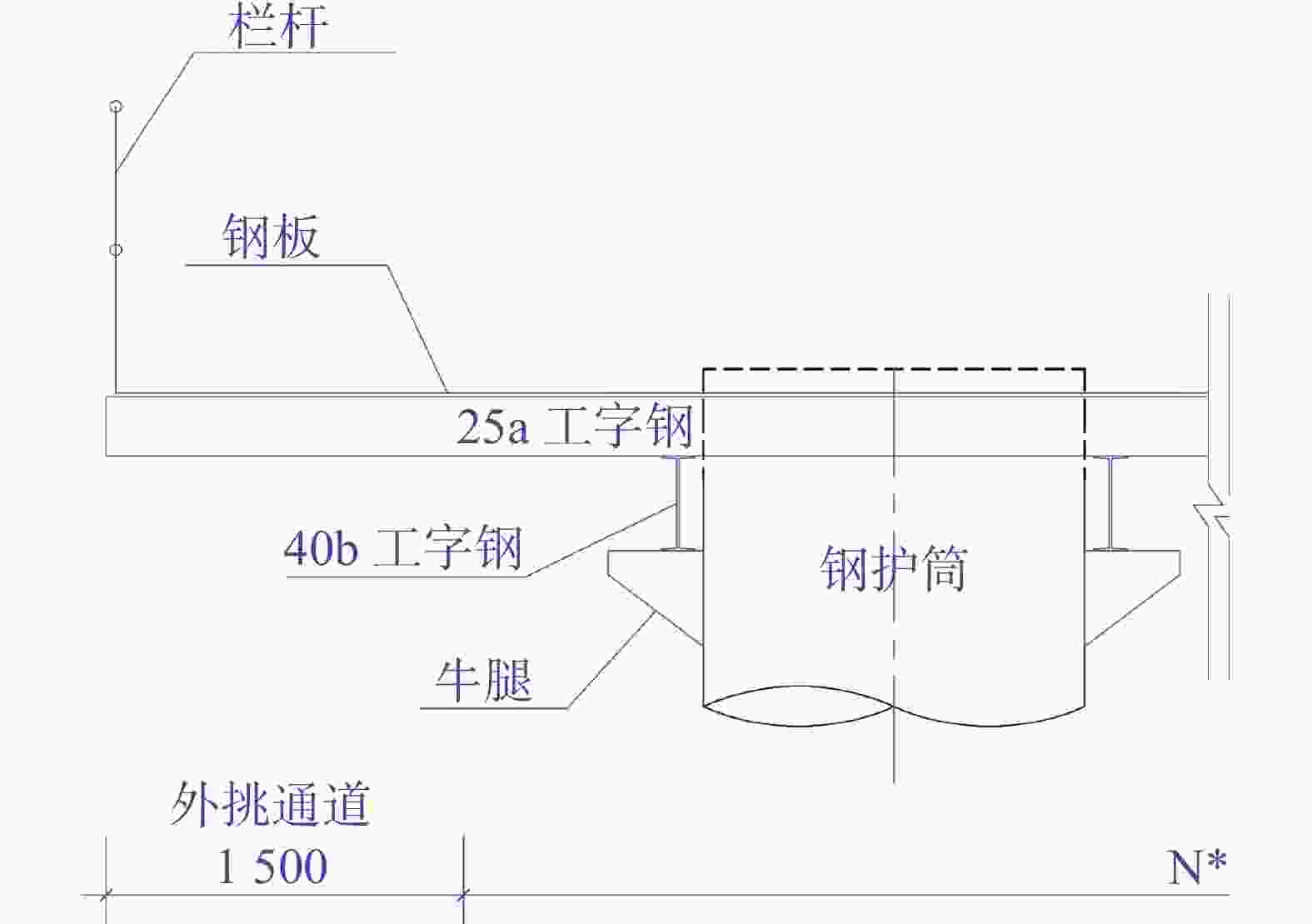

表 1 钢平台面荷载统计表

Table 1. Statistics of steel platform surface load

荷载类型 面荷载/kN·m−2 恒载 钢面板自重 0.69 横梁自重 0.38 纵梁自重 0.64 栏杆自重 0.06 钢管柱及钢横撑自重 20.50 钢横撑自重 1.27 活载 施工荷载 2.00 机械荷载 1.65 水流荷载 1.17 表 2 岩土材料参数

Table 2. Geotechnical material parameters

重度/kN·m−3 弹性模量E50/

kN·m−2黏聚力C/

kN·m−2摩擦角Φ/° 抛石 22.0 1.00×105 27.5 45 粉质黏土 18.8 6.37×103 19.0 11 粉细砂1 19.0 1.17×104 3.0 21 粉细砂2 20.0 1.56×104 0 28 粉细砂3 20.0 2.21×104 0 31 灰岩 21.8 1.00×105 2.5×104 60 表 3 梁与钢护筒参数

Table 3. Beam and steel casing parameters

重度/kN·m−3 弹性模梁E50 /N·m−2 截面面积/m2 惯性矩I2 /m4 极限侧摩阻力标准值/kN 极限端阻力标准值/kN 梁 78.5 2×1011 9.5×10−3 7.19×10−6 \ \ 钢护筒 78.5 2×1011 5.0×10−3 2.01×10−6 70~350 \ 混凝土桩 25.0 3×1010 1.65 2.17×10−1 100~600 4500 -

[1] 向成恩. 岩溶地质桥梁钻孔灌注桩施工技术分析[J]. 交通世界, 2021(20):158-159. [2] Guo F, Jiang G, Yuan D, Polk J. Evolution of major environmental geological problems in karst areas of Southwestern China[J]. Environmental Earth Sciences, 2013, 69: 2427-2435. doi: 10.1007/s12665-012-2070-8 [3] 徐青旺. 岩溶地区桥梁桩基施工技术优化研究[J]. 铁道建筑技术, 2017(12):64-68.XU Qingwang. Study on the Construction Technology Optimization of Bridge Pile Foundation in Karst Area[J]. Railway Construction Technology, 2017(12): 64-68. [4] 覃振洲, 向晖, 袁本哲. 复杂喀斯特地层桥梁桩基钢护筒跟进法施工常见问题与处治措施:以贵州省为例[J]. 工程技术研究, 2022, 7(12): 29-31.QIN Zhenzhou, XIANG Hui, YUAN Benzhe. Common Problems and Treatment Measures for Construction of Bridge Pile Foundation with Steel Casing Follow-up Method in Complex Karst Strata-Taking Guizhou Province as an Example [J]. Journal of Engineering and Technology Research, 2019, 7(12): 29-31. [5] Zhou H, Zheng G, He X, Zhang T, Yang X. Bearing capacity of strip footings on c−φ soils with square voids[J]. Acta Geotechnica, 2018, 13: 747-755. doi: 10.1007/s11440-018-0630-0 [6] Zhou H, Zheng G, Yin X, Jia R, Yang X. The bearing capacity and failure mechanism of a vertically loaded strip footing placed on the top of slopes[J]. Computers and Geotechnics, 2018, 94: 12-21. doi: 10.1016/j.compgeo.2017.08.009 [7] 黑晓丹, 张满彪, 孙海峰, 王斌, 张勤生, 朱权秀, 朱武权, 吕树方. 岩溶地区桩基础设计研究及工程问题分析[J]. 建筑科学, 2023, 39(3):165-173.HEI Xiaodan, ZHANG Manbiao, SUN Haifeng, WANG Bin, ZHANG Qinsheng, ZHU Quanxiu, ZHU Wuquan, LYU Shufang. Research on the design of pile foundation and analysis of engineering problems in a karst area[J]. Building Science, 2023, 39(3): 165-173. [8] 石振明, 沈丹祎, 彭铭, 林杰豹. 岩溶地区桩基施工溶洞处理技术:以吉安永和大桥桩基施工为例[J]. 工程地质学报, 2015, 23(6):1160-1167.SHI Zhenming, SHEN Danyi, PENGg Ming, LIN Jiebao. Karst Cave Disposing Technology For Pile Foundation Construction, Illustrated With-Yonghe Bridge In JI'AN[J]. Journal of Engineering Geology, 2015, 23(6): 1160-1167. [9] 陈铁, 陈劲松, 杨果林, 俞昀. 岩溶发育地区摩擦失效嵌岩桩施工过程病害处治技术[J]. 施工技术, 2018, 47(S1):1280-1284.CHEN Tie, CHEN Jinsong, YANG Guolin, YU Yun. Fighting Failure Treatment Techniques for Rock inlaid Pile Construction in Karst Area[J]. Construction Technology, 2018, 47(S1): 1280-1284. [10] 赵俊逸, 谭文杰, 杨果林, 葛云龙. 长沙景观桥梁桩基隔离钢护筒变形及施工工艺研究[J]. 施工技术, 2019, 48(5):15-18.ZHAO Junyi, TAN Wenjie, YANG Guolin, GE Yunlong. Study on Deformation and Treatment of the lsolated Steel Casing for the Pile Foundation of Some Landscape Bridge in Changsha[J]. Construction Technology, 2019, 48(5): 15-18. [11] 郑博. 岩溶地区房建工程建设中的基础施工核心技术[J]. 四川建材, 2023, 49(4):89-91. [12] 李贵, 张健. 岩溶地区钻孔灌注桩施工技术研究[J]. 工程建设与设计, 2021(2):173-175.Li Gui, Zhang Jian. Study on Construction Technology of Bored Pile in Karst Area[J]. Engineering Construction and Design, 2021(2): 173-175. [13] 钟运志. 岩溶地质条件下的桩基钢护筒跟进法施工技术[J]. 交通世界, 2021(13):101-102. [14] 毕诗堃. 铁路复杂岩溶地区钻孔灌注桩全护筒跟进技术应用[J]. 西部交通科技, 2021(2):119-121,180. [15] 黄龙飞, 常再青, 赵西锋. 岩溶地区桩基施工技术[J]. 铁道工程学报, 2007(S1):90-93.HUANG Longfei, CHANG Zaiqing, ZHAO Xifeng. Pile foundation construction technology in karst area[J]. Journal of Railway Engineering, 2007(S1): 90-93. [16] 鲍庆伟, 高杰, 张书良, 梁岩, 陈全兴. 复杂岩溶地区超大径超长桩旋挖钻入岩施工技术[J]. 世界桥梁, 2017, 45(4):41-45.BAO Qingwei, GAOJie, ZHANG Shuliang, LIANG Yan, CHEN Quanxing. Construction technology of ultra-large diameter and ultra-long pile drilling into rock in complex karst area[J]. World Bridge, 2017, 45(4): 41-45. [17] 邵文勇, 沈世成. 管节式钢护筒在桩基穿越富水岩溶施工中的应用[J]. 公路, 2017, 62(2):99-101. [18] 冯忠居, 徐博熙, 陈慧芸, 夏承明, 蔡杰. 不同溶洞处治措施对桩基承载特性的影响研究[J/OL]. 建筑科学与工程学报: 1-8,2023-10-18].FENG Zhongju, XU Boxi, CHEN Huiyun, XIA Chengming, CAI Jie. Study on the Influence of Different Treatment Measures for Karst Caves on Bearing Characteristics of Pile Foundation [J/OL]. Journal of Building Science and Engineering : 1-8[2023-10-18]. [19] 刘建国, 汪承志, 潘时蕴. 大直径钢护筒、钢横撑与钢筋混凝土桩基联合受力的节点力学性状研究[J]. 水运工程, 2013(483):132-137.LIU Jianguo, WANG Chengzhi, PAN Shiyun. Study on joint Mechanical Properties of large-diameter steel shell, steel cross brace and reinforced concrete pile foundation under joint stress[J]. Water Transport Engineering, 2013(483): 132-137. [20] JTS 144-1-2010, 港口工程荷载规范[S]. [21] 韦建昌, 邵羽, 梁铭, 崔少磊, 蓝日彦, 黄彬华. 超前水平钻探在岩溶隧道地质预报中的应用研究[J]. 中外公路, 2020, 40(3):220-226.WEI Jianchang, SHAO Yu, LIANG Ming, CUI Shaolei, LAN Riyan, HUANG Binhua. Application of Advance Horizontal Drilling in Geological Prediction in Karst Tunnels[J]. China and Foreign Highway, 2020, 40(3): 220-226. [22] 闫小兵, 周永胜. 快速钻探技术在岩溶隧道超前预报中的应用[J]. 工程地球物理学报, 2008(1):89-94. doi: 10.3969/j.issn.1672-7940.2008.01.018YAN Xiaobing, ZHOU Yongsheng. Application of rapid drilling technology in karst tunnel advance prediction[J]. Chinese Journal of Engineering Geophysics, 2008(1): 89-94. doi: 10.3969/j.issn.1672-7940.2008.01.018 [23] Singh, A P, T Bhandari, R Ayothiraman, K Seshagiri Rao. Numerical Analysis of Rock-Socketed Piles under Combined Vertical-Lateral Loading[J]. Procedia Engineering, 2017, 191: 776-784. [24] 邱维衍. 某覆盖型岩溶地质条件下多元复合地基处理[J]. 福建建筑, 2017(232):57-60.QIU Weiyan. Multicomponent composite foundation treatment under a covered karst geological condition[J]. Fujian Architecture, 2017(232): 57-60. [25] 邓尚强. 串珠状溶洞地层中桥桩受力性状的数值模拟[J]. 路基工程, 2015(182):112-114,132.DENG Shangqiang. Numerical simulation of load behavior of bridge piles in beaded karst cave formation[J]. Roadbed Engineering, 2015(182): 112-114,132. -

下载:

下载: